Project Darkside

53Stix - 29/1/20 at 04:29 PM

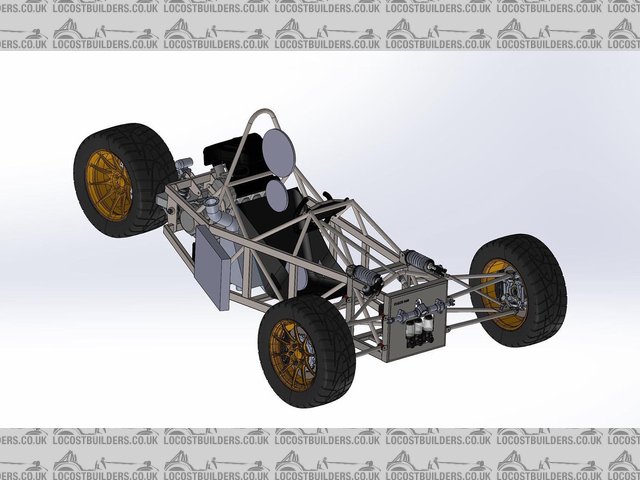

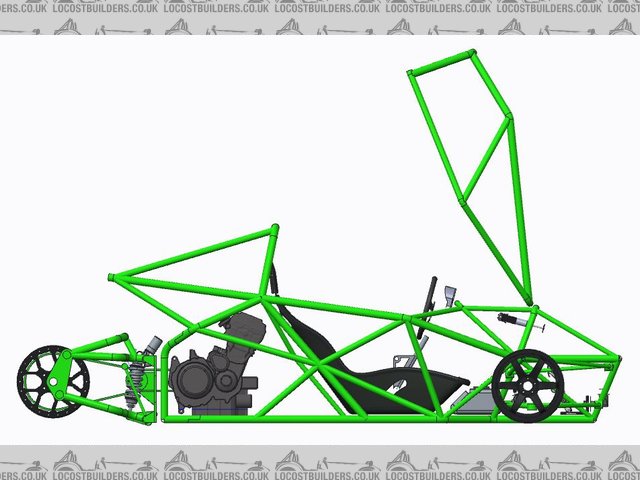

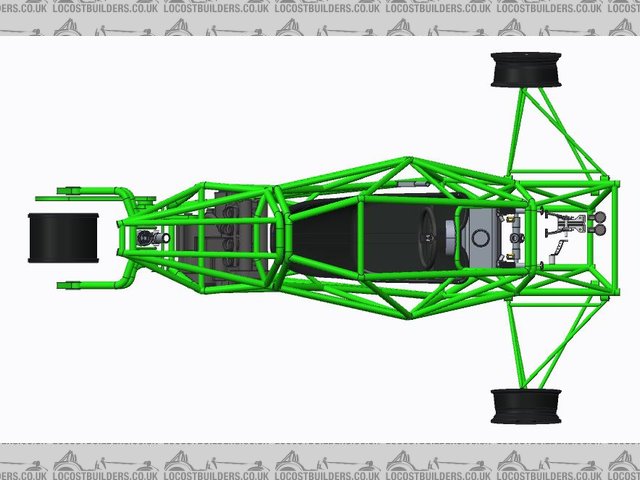

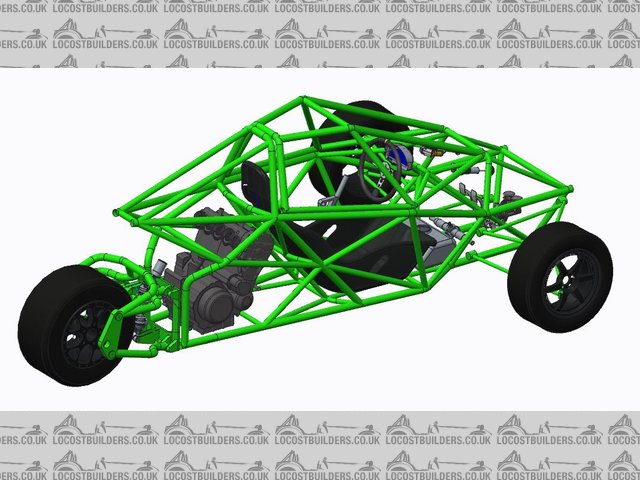

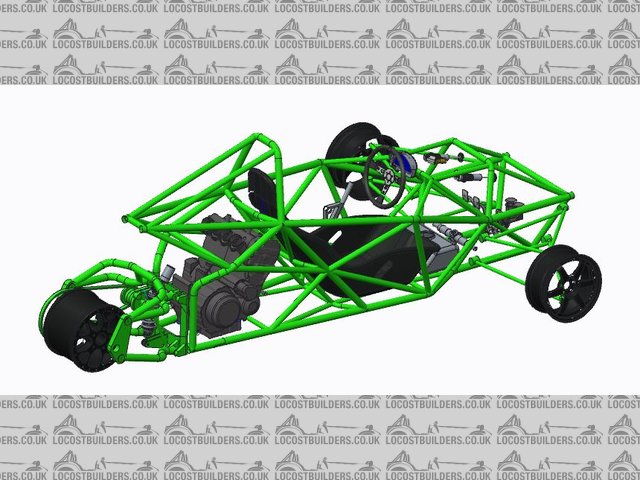

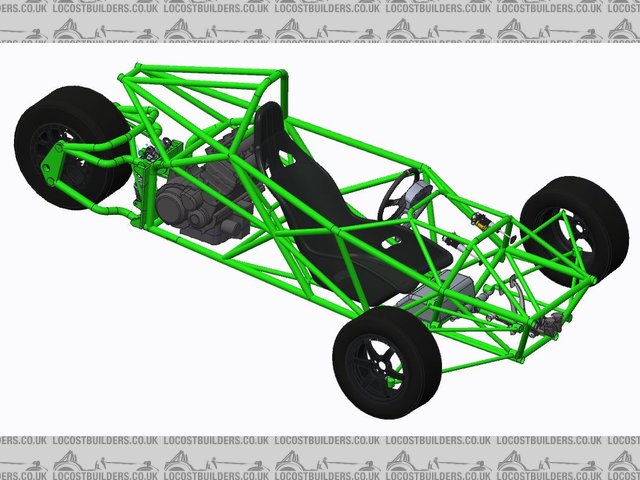

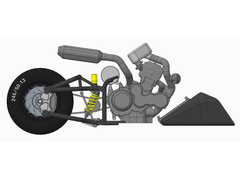

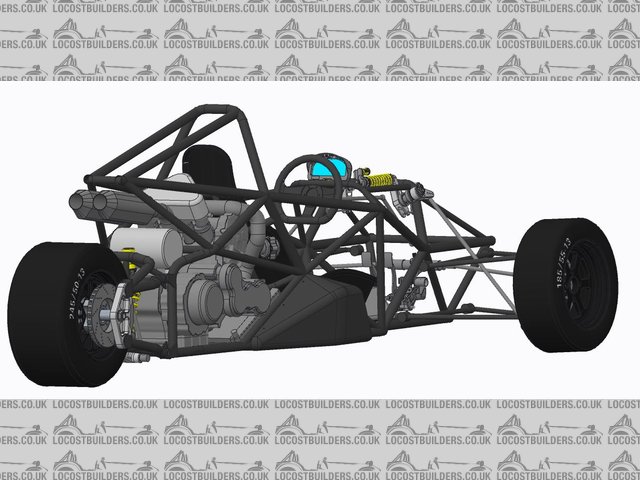

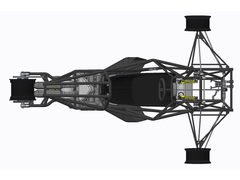

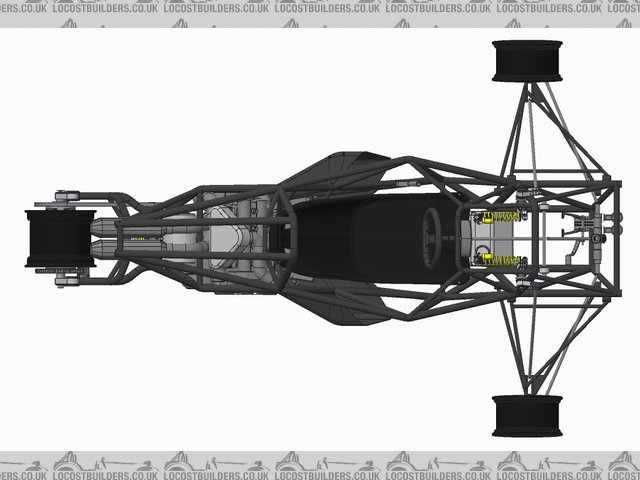

Morning all – a forum newby here seeking some feedback on a little project that I’m planning at the moment, which I’m calling Project Darkside.

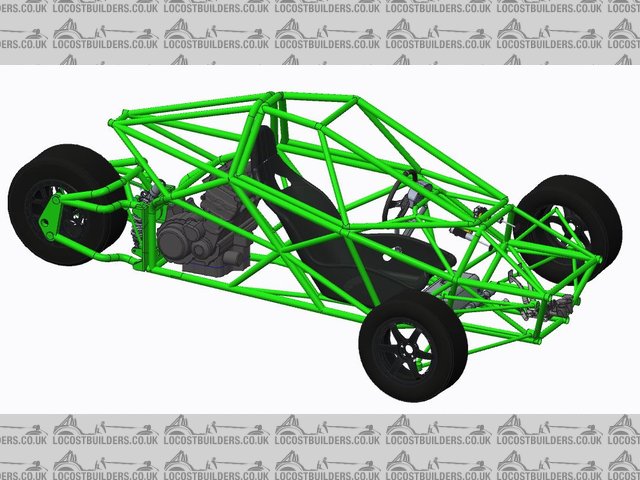

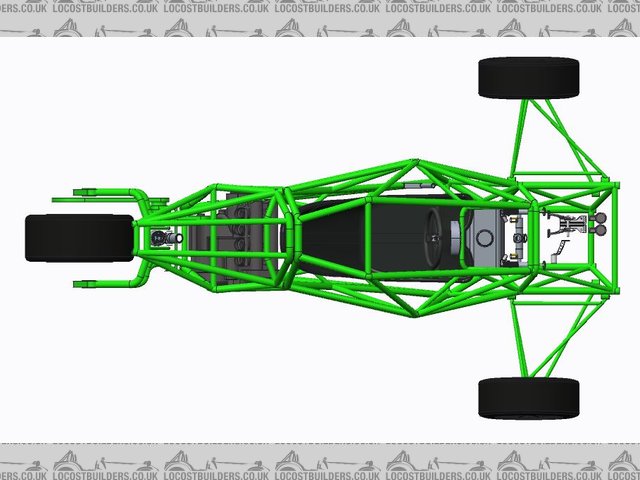

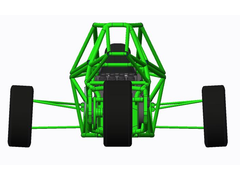

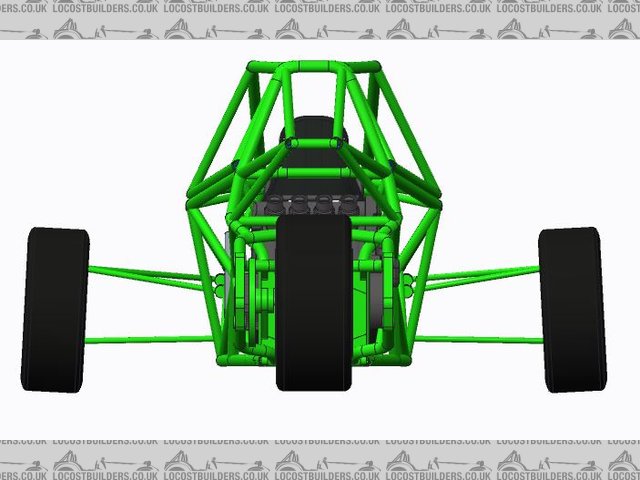

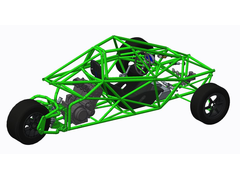

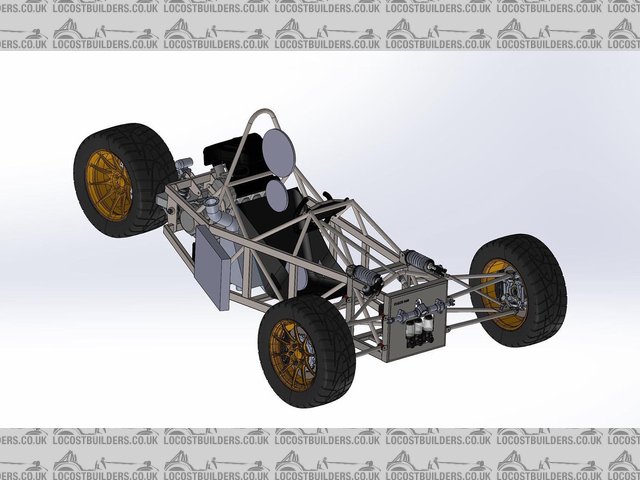

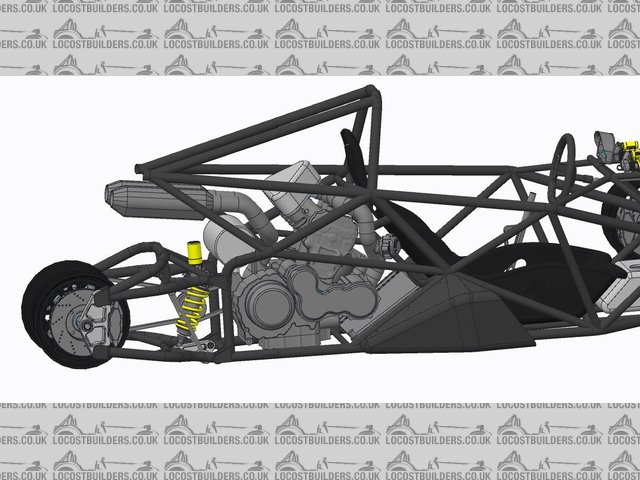

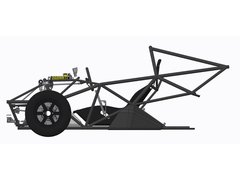

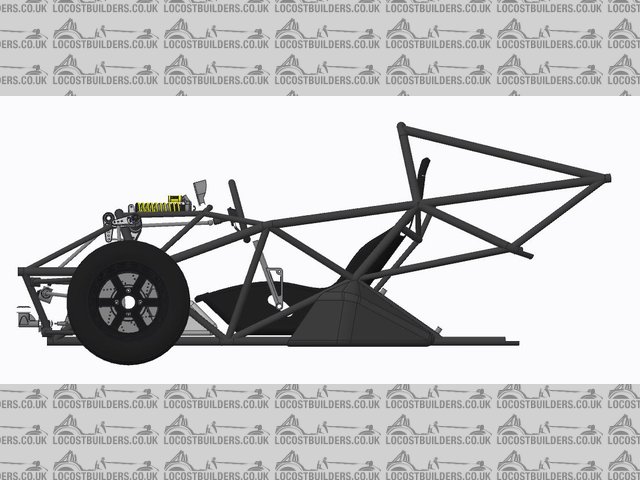

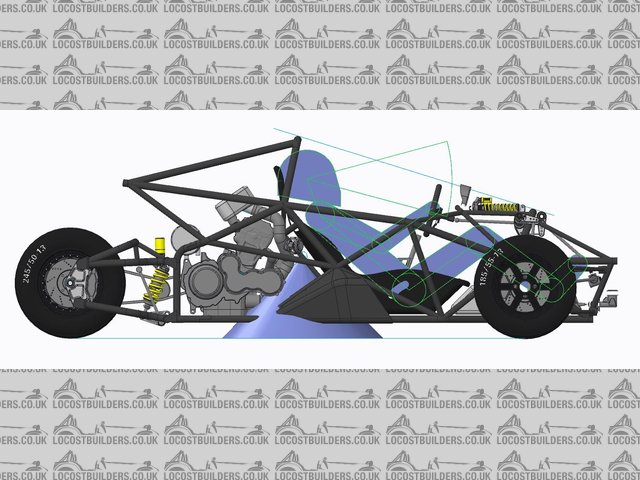

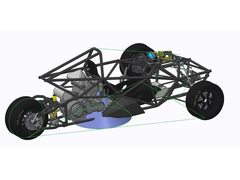

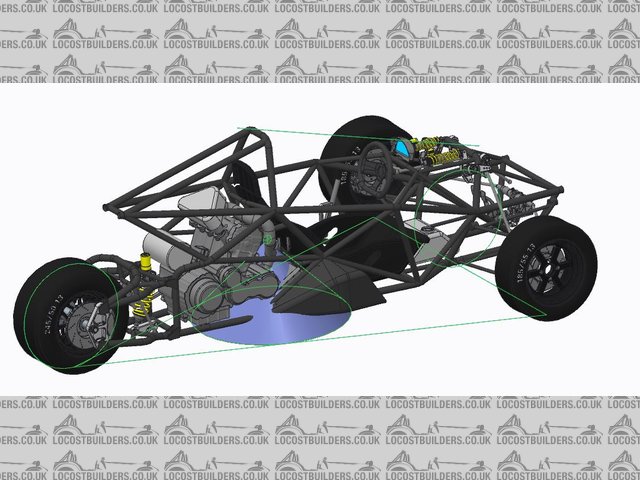

The design is intended to offer a unique driving & ownership experience in the form of a super lightweight single seat reverse trike platform,

combining the immersive cockpit environment of a single seat racing car with the performance & accessibility of a superbike, at a fraction of the

cost.

The concept benefits from several distinct advantages, not least of all being that it can be built, developed, stored, maintained, repaired and

transported using considerably less space, expertise and cash than an equivalent four-wheeled vehicle.

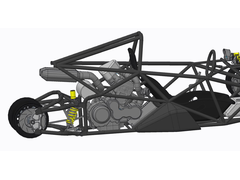

As you will appreciate, many key parts can be sourced from a donor production motorcycle (potentially to include, but not limited to, powertrain,

cooling system, throttle bodies, airbox, exhaust headers, rear spring damper, linkage, dash, loom, brake disks, calipers, rear wheel etc), with many

other elements reduced in cost or eliminated altogether by virtue of the single rear wheel design (e.g. differential, driveshaft assemblies,

suspension assemblies, uprights, wheels/tyres, brakes etc).

A modular design philosophy means that the concept can be easily reconfigured to accept a wide variety of motorcycle engines; each offering a proven

and power-dense powertrain with integrated sequential gearbox and back-torque limiting clutch, plus the ability to shift seamlessly up and down the

box. Just the job!

The result should be a driving experience unlike any other, with an ultra low CoG and target wet weight of ~260kg meaning circa ~700bhp/ton (assuming

a reasonable ~180bhp from a modern 1000cc naturally aspirated motor).

The concept demonstrator would focus on proving out the idea quickly and efficiently, for example adopting existing COTS corner assemblies from a

Caterham or similar in place of a custom design. It would also feature considerable adjustability, so that the impact of geometry/suspension changes

can be explored in depth before the chassis design is fully firmed up.

Should the response be positive then my intention is to offer the opportunity to support the project through a Crowdfunder campaign, as a means of

accelerating the delivery of the first concept demonstrator and some basic tooling. As incentives I’m planning to offer the opportunity to drive the

first prototype vehicle on track, join an engineering steering committee, commission a vehicle at cost and even take an equitable stake in the

creation of a dedicated company that can further advance the design and produce these in (very) low volumes.

My background is formerly in mechanical design engineering within the motorcycle industry, and I currently work for a motorsport/engineering

consultancy so have plenty of very capable resource around me to support with the engineering & productionisation. However, what’s lacking is

input from people who may actually want to use of even buy the vehicle – hence I’m keen for some feedback from fellow Locost Builders!

Finally, I do acknowledge that the three-wheeled layout isn’t for everyone, and that if you’re genuinely interested in going seriously fast then

clearly this isn’t the vehicle for you (or, I’ve not explained what I’m trying to achieve here very well…) However, look at this through fresh eyes

and hopefully you share my enthusiasm for what could be a seriously fun and capable little toy!

So, there you have it! I’d be most interested to hear your thoughts and any constructive criticism… what do you think?

Best regards,

-Rob

53Stix - 29/1/20 at 04:29 PM

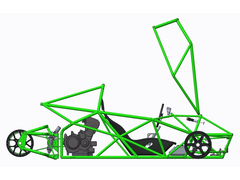

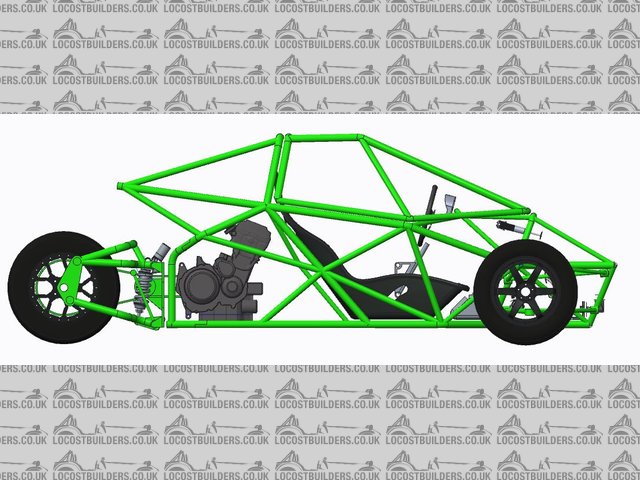

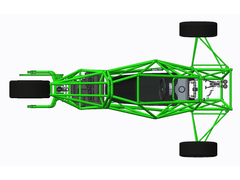

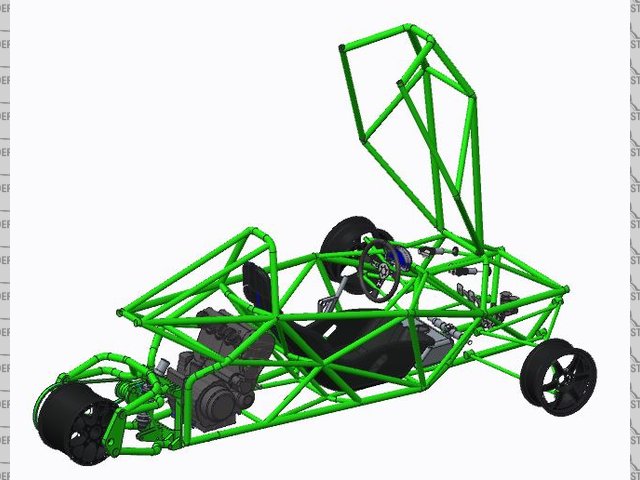

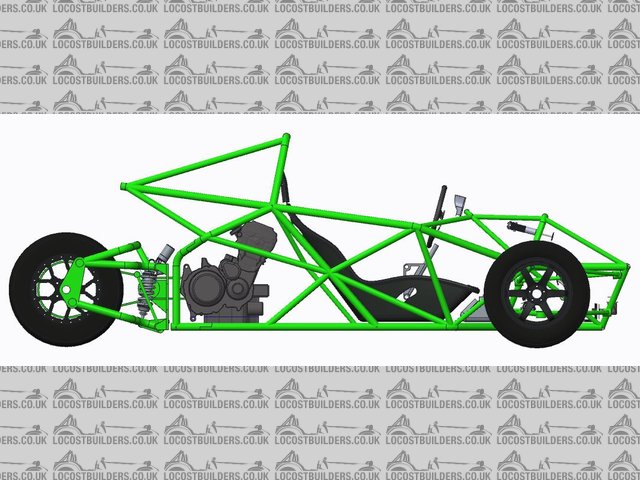

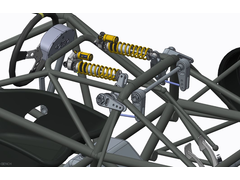

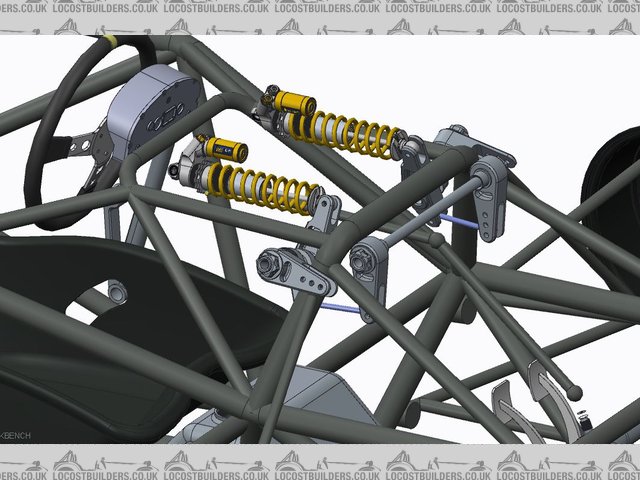

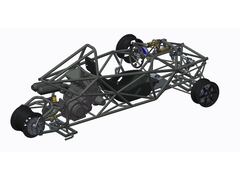

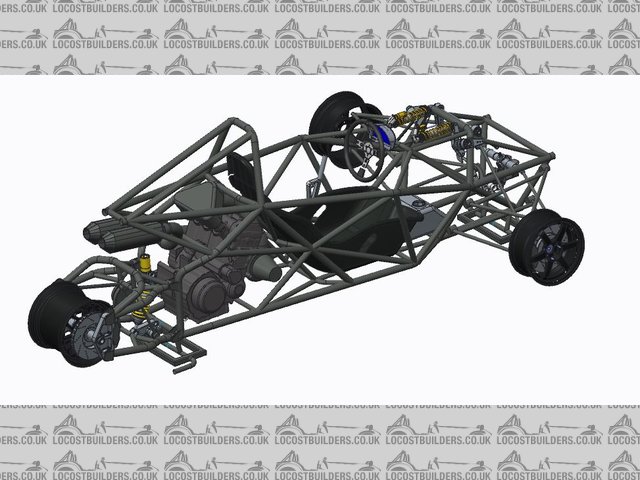

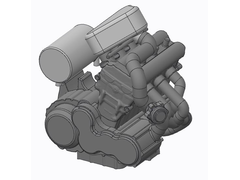

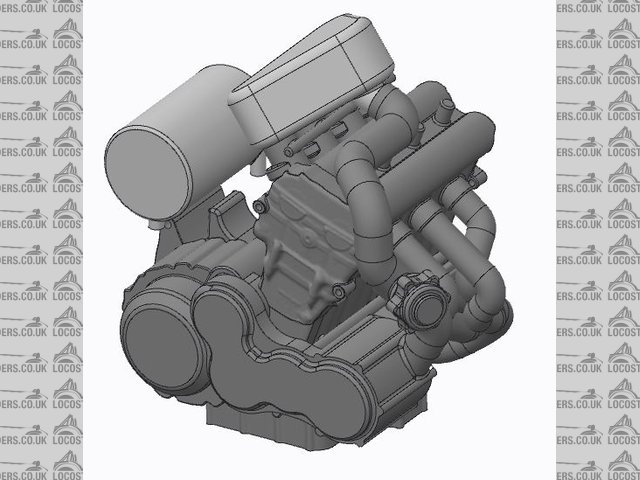

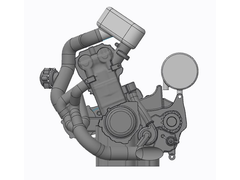

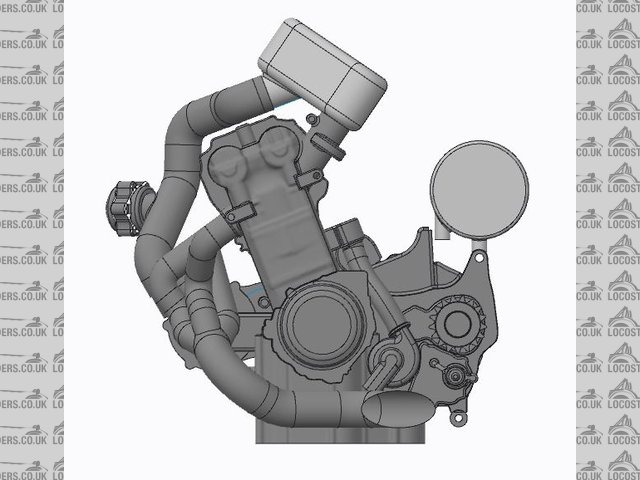

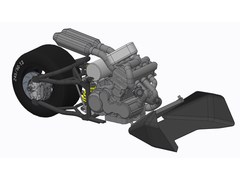

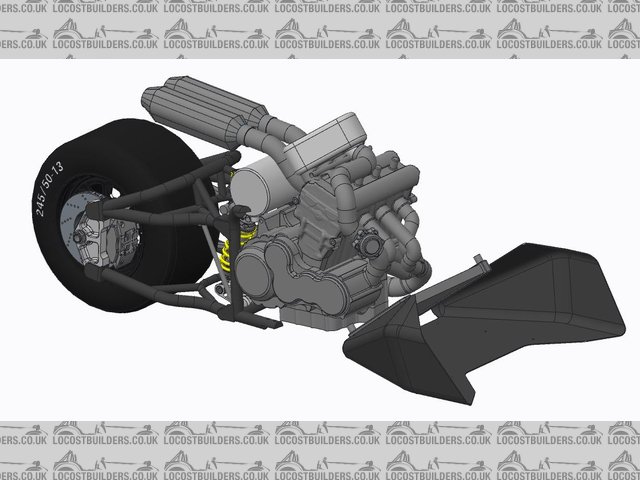

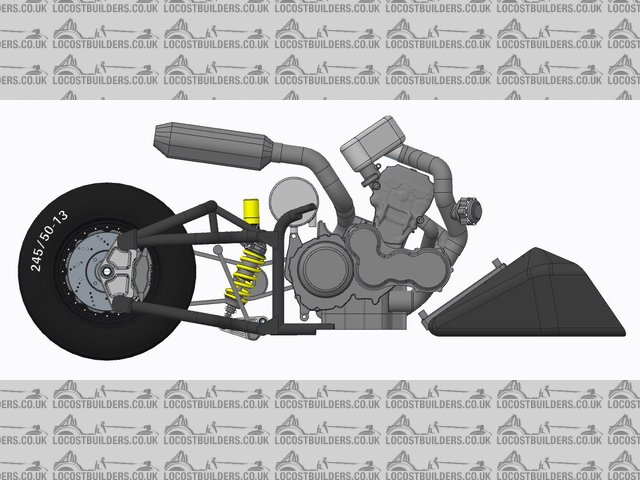

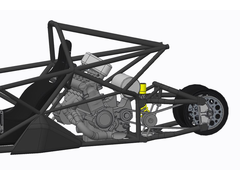

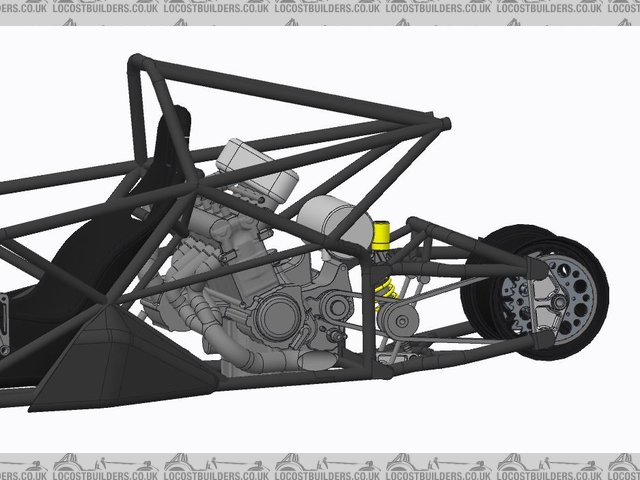

A few more images to whet the appetite...

Description

Description

Description

Description

Description

Description

Description

Description

Description

Description

Description

[Edited on 30/1/20 by 53Stix]

ReMan - 29/1/20 at 11:22 PM

WELCOME ABOARD

Nice designs. not the first of course. I like the hinging lid, though whether it will be practical and add much value, is debateable

Its a bit slow here at the moment, but I'm sure you'll get some constructive feedback soon

There is a Trike section here, so have a good look through it,

JC - 30/1/20 at 07:49 AM

Firstly, welcome aboard! Good to see new members and fresh ideas.

I love the idea of the design - just a couple of observations.

Firstly, by making it strictly single seat you are limiting the market. Most people will, at some stage, want to take someone out in their creation,

or even have a weekend away. I get the ‘single seater experience’ but might be worth looking at. Google the Light Car company Rocket....

Secondly, I’m not keen on pedals in front of the front axle line - even a minor front shunt means ankles as a crumple zone....

Finally, it may be that simplifying your frame solution, whilst taking it away from the perfect engineering solution, brings large cost benefits in

terms of the time to manufacture a chassis, for minimal actual performance loss.

Other than than, keep at it and good luck!

Mr Whippy - 30/1/20 at 08:33 AM

Ok well my first comment would be it is far from a new concept, there are loads of tadpole trikes designs already and a very limited market for them,

just a google search brings up tons.

Disadvantages would be

• no heater

• no weather protection

• very noisy

• sitting like that being blasted by the wind even on a hot day will be painfully cold

• still as wide as a small car so you can’t filter in traffic like a bike, one of a bike main benefits

• lower to the ground than a bike so overtaking harder to judge safely

• much heavier than a motor bike so performance is down

• those wide wheels will add a lot to road friction and air drag compared to a motor bike

• no storage

• can’t take passengers

• less aerodynamic than a motorbike (unless fitted with a streamlined shell and wheel spats)

• combines the disadvantages of a car with the disadvantages of a motorbike with little if any benefits

I looked a building a trike myself, the only reason to do so was to produce an extremely fuel efficient machine by using a narrow and long fully

enclosed streamlined bodyshell with a 250cc injected engine, narrow tyres enclosed in full wheel spats. I didn't bother as my little car was so

good on fuel...

If that canopy frame is meant to be part of the roll protection it is going to have to be very securely held shut or it may end up making things worse

if it strikes the driver in the head coming off. Tbh I'd not have it or instead use a lightweight alternative if it's just to hold on a

windscreen.

You say low a CG but the first thing I thought when I saw it was that looks very top heavy for a trike...

[Edited on 30/1/20 by Mr Whippy]

Doctor Derek Doctors - 30/1/20 at 09:15 AM

As someone who's been through a similar process I can offer some constructive criticism... But it is criticism none the less so don't take

it personally.

My fist point would be that there are loads of trike out there that range from the very cheap bike based like the tR1ke (which looks a lot like what

you are doing) right upto the Polaris. Where does this sit in the market? Apart from being single seater how is it unique or different?

Have you considered that you are building a race/track car that won't actually be allowed on any sprints or hillclimbs? If its a very hardcore

driving experience not being able to enter even the lowest level of timed motorsport may put people off... And with it being single seater you are

going to struggle to convince track day organisers to let you out as well. Leaving owners with a very harsh road car.

On the engineering side, how is the engine going to go into the frame? There appears to be no hole large enough, and even a hole large enough needs

more clearance than you think.

How is the driver going to escape in case of it ending up on its side/roof? (a perceived and real issue on 3-wheelers)

As already mentioned the feet in front of the axle is a safety no-no. Also I wouldn't be happy with the steering column dropping right down

between my legs.

53Stix - 30/1/20 at 10:41 AM

Thanks for the comments, all... good food for thought.

Very aware that the RT layout has been done many times before - infact the Spartan Trike was

one of the key inspirations for me.

I'm undecided on the hinging canopy/lid. I like it aesthetically but it adds cost, complexity, risk and mass. Whether it stays or not remains to

be seen, but it's certainly low priority.

In terms of rollover protection I've accommodated good clearance between the drivers helmet and the plane created by the points of contact with

the floor, so should be safe in this regard. Or, at least as safe as a conventional formula-style chassis.

I appreciate the concern over pedals infront of the axle. FSAE (Formula Student) seem to advocate this design with the use of a dedicated front impact

absorber so perhaps that would be a sensible route forwards? Shifting the feet to be behind the axle drives the whole vehicle proportions up by virtue

of an extended wheelbase, which prompts an increased track width, which means higher mass etc etc. Nonetheless, I'll continue to consider my

options and appreciate the input.

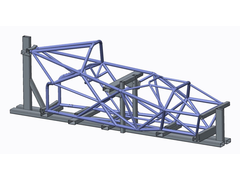

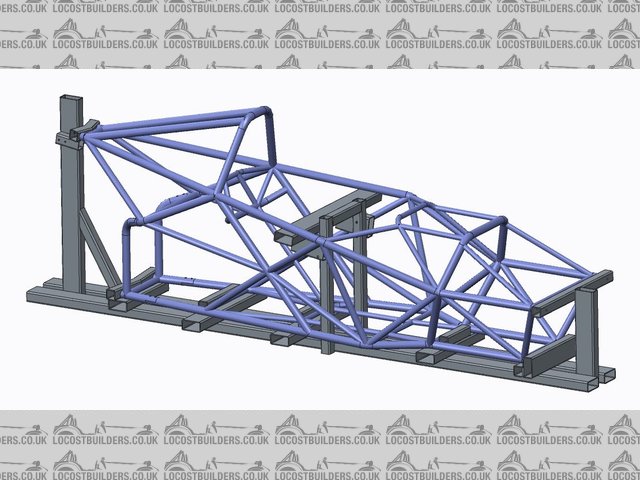

Also appreciate the observation around frame simplification - it's a topic that I've had in my mind for a while. The current design would

utilise compound bends on only two frame spars so the rest can be bent up using a conventional bender/mandrel using widely accepted rules of thumb

(e.g. 2xD bend rads etc). Nonetheless fixturing and fabrication time/effort would be considerable with the current layout - it's just a question

of striking the right compromise I guess.

@ReMan - have noted the Trike section and am working my way through it. Thanks!

@JC - Thanks for recommendations, duly noted. The single seat is a fairly firm requirement in my mind as I'm aiming this to be more track focused

than road focused... a two seater design would be an interesting parallel design activity though! I'll have a think...

@MrWhippy - I'll pop you down on the pre-order list and look forward to receiving your deposit in the post

@Doctor Derek Doctors - Thanks and no worries. Perhaps it's engineering snobbery but I must admit that when I look at the other RT's

available I see massive engineering compromises which just put me off. Having said that I have no answer as to what makes mine truly unique or

different - only that I think it looks cool and perhaps could outperform the competition, all other things being equal...?

Competing is absolutely on the agenda, albeit that you're quite right that the current options are limited. Perhaps it's ignorance on my

part but I'm hoping that the "build it and they will come" approach will pay dividends. Nothing ventured, nothing gained...

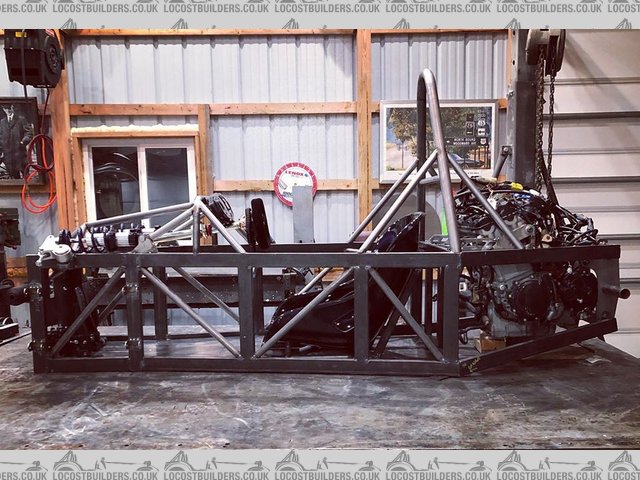

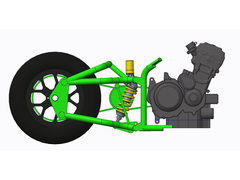

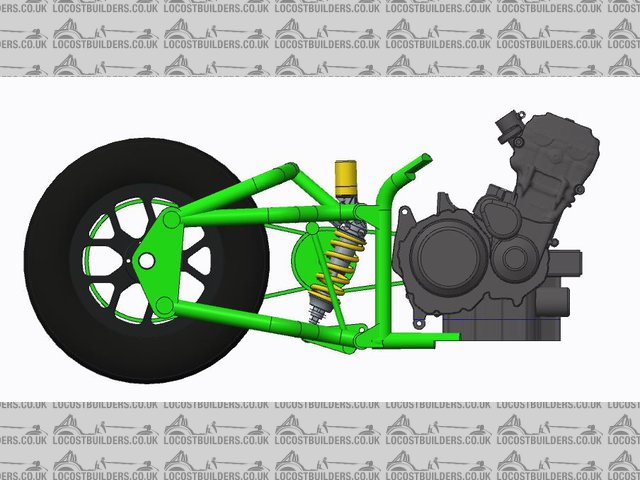

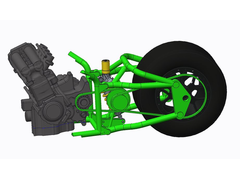

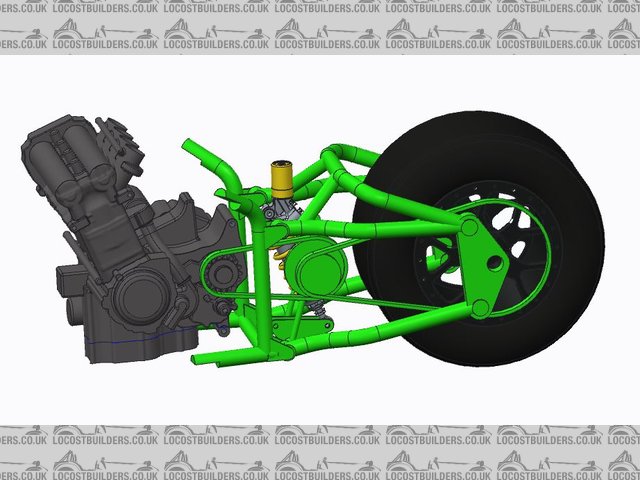

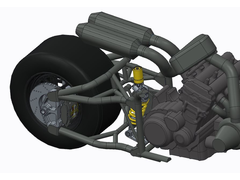

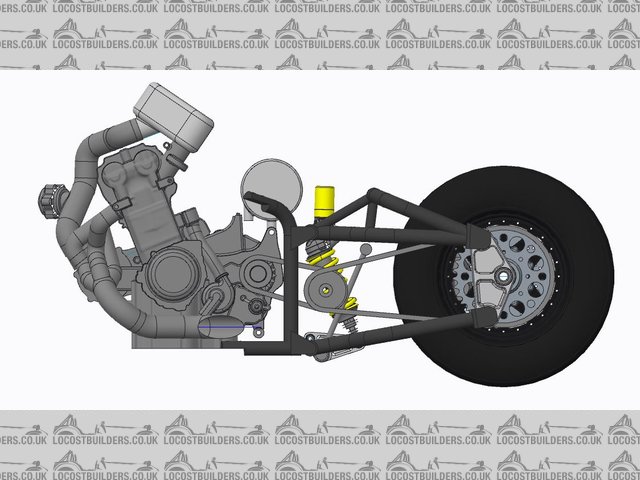

Engine fitment will be achieved through a modular rear end, which allows for the entire wheel, transmission, suspension and engine assembly to be

sub-assembled before fitment to the chassis. Pretty horrendous mating geometry, I grant you, but until such time as I've got confidence in making

any more than one or two of these things I'm happy to adopt features which require alot of hand fitting.

Description

Description

Sam_68 - 30/1/20 at 11:34 AM

quote:

Originally posted by 53Stix

.... Perhaps it's engineering snobbery but I must admit that when I look at the other RT's available I see massive engineering compromises

which just put me off.

The thing that's striking me with your design is that you've clearly gone to a lot of effort to create a very well triangulated

spaceframe... for a vehicle that actually doesn't need much torsional stiffness.

The only thing that puts any significant torsional loading on the frame of a reverse trike is the moment between the rear tyre contact patch and the

swing-arm mountings, which isn't very great (call it the load on the tyre at 1g x the vertical distance to principal axis of the moment of

inertia).

One of the major benefits of RT's is their simplicity and the light weight that comes along with it, so engineering snobbery should be

disparaging of anything that erodes that unnecessarily.

Mr Whippy - 30/1/20 at 01:11 PM

quote:

Should the response be positive then my intention is to offer the opportunity to support the project through a Crowdfunder campaign, as a means

of accelerating the delivery of the first concept demonstrator and some basic tooling

So... your going to take deposits to fund the first one, are you sure you can supply to match demand? is there any demand in the first place? If it

doesn't work out are you going to give me back my deposit...or vanish into the night

Have you done a business model to work out if production costs, SVA testing, wages, tooling costs, building costs etc etc, can all really be lower

than the price people are going to want to pay? Very hard to do with low production numbers. Wonder what the government tax would be too for such a

venture??

I see so many crowd funding startups that fall over and run off with the cash when the Utopian dream they had doesn't come true they way they

wanted. Not trying to be a party pooper but this is a business you want to setup but is this even viable in the first place if you are competing in an

already crowded and very limited market. If I was a Dragon, would I invest my cash in this?

[Edited on 30/1/20 by Mr Whippy]

bart - 30/1/20 at 03:40 PM

Hi , if that's your dream go for it although I would add some words of caution

1) make sure of your intended market

2) what ever you think it will cost it will be it will be 4 to 6 times that and its more likely to be 6 times u2u me if you want advice

3) make the chassis less complicated easier to tool ect

4) your front suspension looks very Formula based , bare in mind these are designed to rip off in a crash and save the chassis

ie: they are to flimsy

don't forget to add your lights , bare chassis looks good but adding lights can make it ugly if it does not blend with the overall design

5) if your going to add panels then design them now don't leave it till the chassis is done

6) short will make the trike unstable and prone to rear overtaking the front !

7) don't forget fuel and cooling, again design it in now

8) if it a bare frame design where you going to route pipes and wiring ect ?

9) final word of caution , what you have done now is i'm sorry to say the easy part by a long way , you still have 99.9% to do

bare this in mind i'm not exaggerating .

sorry some more thoughts : go for top mount steering , as other have said keep the steering above your feet , if you need pointing in the correct

direction for uprights ect u2u me , don't try and design everything use what's out there it will save years of work and mistakes. I also

have a load of bits and also cad models if you want.

Be ALERT the uk needs more LERTS !

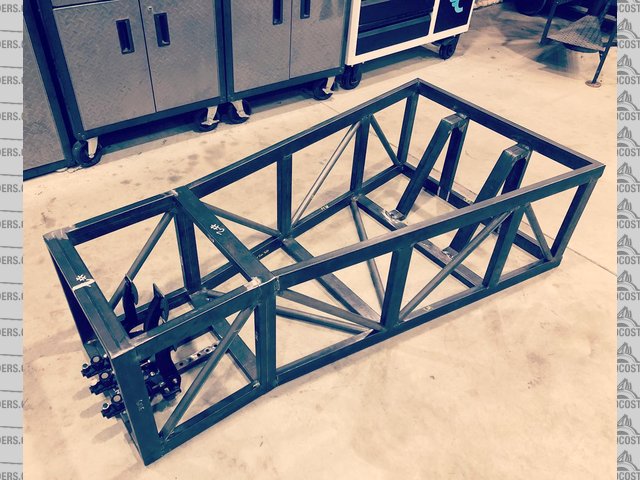

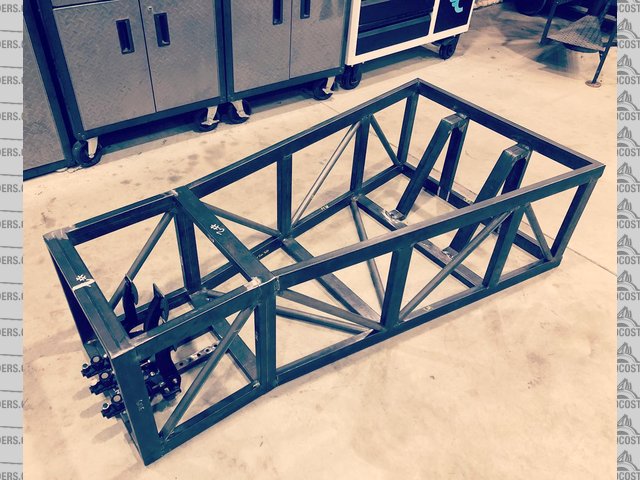

53Stix - 31/1/20 at 09:28 AM

@Sam_68 - appreciate the response. The chassis's pretty light at the moment and whilst I could get some more weight out by removing/reconfiguring

some members, the layout has been driven more by the need to create a strong monocoque which stitches together hardpoints in a logical manner, rather

than outright stiffness. Nevertheless perhaps there is a need to re-assess...

For ref, in T45 using some 'normal' section sizes the chassis (bare frame inc. rear subframe) currently weighs in at around 34kg including

weld fillets but excluding the canopy and any brackets.

Please may you explain your comment about a torsional load being induced by the (central) rear wheel - I'm afraid you've lost me on that

one...

@Mr Whippy - relax, I'm very aware this isn't going to be a multi-million pound venture. In the first stages it'll involve me, my

garage and a heck of a lot of late nights! If anyone else wants to support along the way then that would be most useful

This exercise (i.e. this forum topic) is merely to understand the opinions of like-minded people before I commit to anything. If the feeling is

negative then all that will happen is that I'll build the design in my own spare time and to exactly the spec that I want. If however there is,

by some miracle, a genuine interest/enthusiasm then an equity stake in a limited company, and/or crowdfunder bid to help accelerate the development

and tooling etc, may be a sensible route(s) forwards. Moreso, a limited company seems a sensible route to formalise the whole affair rather than

accepting all costs and liability on my own fair shoulders - wouldn't you agree? I'm sure the UK Govt would agree...

Either way, judging from the 12+ disadvantages you were quick to point out my assumption of receiving a deposit from yourself was most certainly made

in jest.

@bart - cheers for the pointers. Will u2u in the next few days for some more info.

Re. point 2 I'm keeping a running BOM with all my suppliers and prices in check, so would like to think it'll end up being a little less

than 6x current estimates.... either way I'm sure it'll soak up whatever I allow myself to spend on it, as these things always do!

Re. point 4 as per Formula cars, I too want my suspension to be sacrificial in the event of a crash, otherwise the geometry is compromised (e.g.

shorter stiffer control arms) and the weight is increased significantly. As long as it doesn't pose a safety concern, then I'm happy with

that.

Re. point 6 I'm keen to accommodate as much adjustability as possible in the initial concept demonstrator, with wheelbase and track width being

key parameters. The modular rear end and simplistic control arms should allow me to explore things fairly easily. It'll be fun trying things out,

that's for sure!

Re points 7/8/9 Also aware of the magnitude of work yet to do. I wanted to get it out of CAD and onto a welding table as early as possible to get a

proper feel for geometry and proportions, so whilst I've already modelled representative exhaust runs, inlet systems, cooling systems etc

I'm not set in stone on any of these and wanted to physically offer up parts and look at different layouts in real life before committing to

anything.

Re uprights I'm keen to use existing production corner assemblies on the first vehicle (i.e. upright, hub, disk, caliper etc) to just get it up

and running quickly and cheaply. They need to be compatible with 13x7's on a 4x100 PCD so at the moment I'm thinking that some Caterham

uprights are my most sensible route forwards. Interested to hear your thoughts

Thanks again all!

-Rob

Mr Whippy - 31/1/20 at 12:44 PM

Not so much disadvantages but opportunities, depends on how you look at it

• no heater - fit one or position the radiator so that the air exhaust from it flows over the driver.

• no weather protection - clip on screen or detachable roof

• very noisy - panel in the engine

• sitting like that being blasted by the wind even on a hot day will be painfully cold - body panels...

• still as wide as a small car so you can’t filter in traffic like a bike, one of a bike main benefits - scuppered with that one

• lower to the ground than a bike so overtaking harder to judge safely - no fix there either

• much heavier than a motor bike so performance is down - keep it as light as possible, less is more, does it need to be so strong?

• those wide wheels will add a lot to road friction and air drag compared to a motor bike - don't think you need them, more for aesthetics

• no storage - panniers, luggage rack, a boot?

• can’t take passengers - could be either 2 versions or maybe a longer wheel base that can do either

• less aerodynamic than a motorbike (unless fitted with a streamlined shell and wheel spats) - obvious fix

• combines the disadvantages of a car with the disadvantages of a motorbike with little if any benefits - address the above and you'll

have a bigger market

53Stix - 31/1/20 at 02:26 PM

Understood and appreciated - thankyou!

Worth noting that this vehicle is intended to be used hard and focussed on high performance (yes, I know it's a trike and thus won't ever be

as fast as a car....) and with that in mind a few of your very valid points start to move away from that vision, i.e. wind blast, engine noise,

storage, seating etc

Maybe a more road-bias derivative would be a sensible idea after the initial concept has been created, i.e. with increased ground clearance etc... I

certainly need a better understanding of the IVA (or MSVA?) implications if road use is to be a priority, and there's bound to be a few

left-field requirements that I've not encountered.

Wheel sizes is an interesting one... I must admit that the current wheel sizes are the smallest they've been since I started the design process,

having worked their way down from 17"+ to 13s front and rear. Current intention is a 185/55-13 and 245/50-13 respectively, with dim'ns taken

from the Avon ZZS. Exact wheels are still TBC and will likely just be whatever pops up in the classifieds, but current intention is along the lines of

the 13x7 on a 4x100 PCD up front, with a bespoke split rim at the rear which I can get sorted fairly easily through work.

Of course if budget is really tight I can always just adopt the OEM motorcycle rear end in it's entirety, including wheel, brake, swingarm,

linkage and spring damper. Food for thought...

Cheers,

-Rob

fishywick - 31/1/20 at 02:47 PM

One (as far as I am concerned) huge advantage of a trike is that it needs the much less stringent and simpler MSVA.

You have obviously seen the MEV, now Rebel Performance. Two other recent ones are 2rike and TWS Racing.

2rike was a toolmaker from Yorkshire and uses all except the front end of an R1, details on facebook. I recall he had some very tidy home made hubs.

He produced two or three, not sure if they were sold or not.

TWS was a French builder and again used the swingarm and fuel tank from an R1, also on facebook. I believe this was a one off only.

Sam_68 - 31/1/20 at 08:20 PM

quote:

Originally posted by 53Stix

Please may you explain your comment about a torsional load being induced by the (central) rear wheel - I'm afraid you've lost me on that

one...

The point is that it's negligible.

If you think about the normal way a chassis would be twisted on a 4-wheel car (by one 'axle' being deflected in roll or bump relative to the

other), then you'll see that they simply don't exist on a three-wheeler, because there's no roll resistance at the end with the single

wheel to react against twisting of the two-wheeled end.

I would have simply said that torsional stiffness is not a problem, period, but this being the internet, some smart-ass would have turned up to point

out that it's possible to get a small amount of torsional loading from the moment between the side thrust of the contact path on the single wheel

x the distance between that contact patch and the principal axis (colloquially: the 'mass centroid axis', thought they're actually not

quite the same thing). There's also the potential for a small amount of torsional loading simply from the inertia of the sprung mass.

So I thought I'd get in there first, to neutralise the anally-retentive hair-splitters....

But it is a SMALL amount of torsional loading in both cases, so the torsional stiffness of a chassis on a trike is well down your list of

design objectives, in cold, hard engineering terms.

coyoteboy - 1/2/20 at 12:38 AM

It's worth noting that FSAE car designs are based around a very specific set of rules and contrived applications. The courses are relatively low

speed and very controlled in terms of safety, meaning the cars can be relatively inherently safe. Feet in front of axle doesn't bother me too

much - axles don't add much in an impact, they usually fold backwards. Steering column between my legs wouldn't bother me too much either if

I had a decent harness and structure around me. However it's a right PITA to get in and out of a car with a column between your nads.

[Edited on 1/2/20 by coyoteboy]

JC - 1/2/20 at 07:58 AM

I think it was the designer of the Buckland who had a strong opinion on torsional loads in a 3 wheeler - along the lines of that they exist and the

very last thing you want is unintentional rear wheel steer....

Sam_68 - 1/2/20 at 08:22 AM

quote:

Originally posted by JC

I think it was the designer of the Buckland who had a strong opinion on torsional loads in a 3 wheeler - along the lines of that they exist and the

very last thing you want is unintentional rear wheel steer....

...and yet he was happy to design the B3 with a very simple, very traditional ladder frame?:

Certainly, the rear swing arm needs to be stiff, to avoid any rear steering deflection (and I'm not keen on the OP's design, just from

looking at it, without any stress analysis), but apart from that, you'd need really significant amounts of torsional deflection of the chassis

itself to result in any noticeable rear-wheel steer. It's very difficult to see how you'd manage to load the chassis in such a way that

would cause that.

53Stix - 1/2/20 at 01:38 PM

@fishywick - having skimmed through the MSVA document I must admit I'm pleasantly surprised... this is a definite advantage that I must admit I

had not fully appreciated!

TWS have a couple of cool videos on YouTube - this one in particular is really cool... Great

project and a super benchmark.

@Sam_68 - on the basis that there's a lot of big words and I don't honestly understand them all, I'm happy to go along with your

statement of "torsional stiffness is not a problem"!

Ref. the rear swingarm setup, agreed that the current layout is far from ideal. This was a half-hearted effort at again stitching together notional

hardpoints based on squat geometry and suspension kinematics. The current design is both unconventional and unlikely to be what I end up with, both in

terms of the linkage design and the arm(s) themselves. Any good benchmarks or reference info greatly appreciated!

@coyoteboy - constructive comments, thanks!

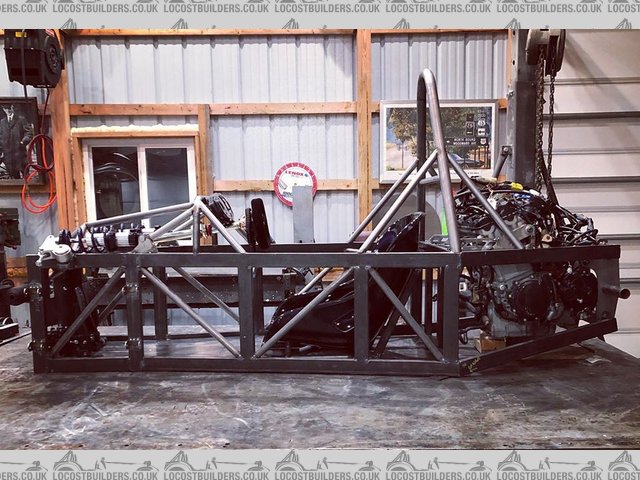

53Stix - 3/2/20 at 08:58 AM

Guys, guys GUYSS!!

Check this out... stumbled across Corso Concepts over the weekend. Looks like a super benchmark

that, conveniently, seems to have taken on board many of the above comments already.

That being said, the chassis looks pretty rudimentary and very heavy, and the ROPS seems insufficient.... but they're several steps ahead of me

so fair play to them!

Description

Description

Description

Description

Description

Description

Mr Whippy - 3/2/20 at 12:46 PM

hmm crumple zone... would that be the footwell? where your feet use to be before they were amputated

tbh it's one of those designs I do wonder just why they went for 3 wheels and not 4, to save on the price of a diff? a little bit more chassis?

the rear trailing arm looks much heavier than a suspension setup like the front, were is the advantage?

53Stix - 3/2/20 at 12:52 PM

Ever the positive, Mr Whippy

bart - 3/2/20 at 01:31 PM

that's one big mass of a frame for a trike ! re corso

at least its not as feet forward as the dark side version

although looking at the size of the chassis members the crumple zone is the rear wheel

be alert Britain needs more Lerts

Keep on trucking ! before they ban it

fishywick - 3/2/20 at 04:30 PM

I suspect you know that 'darkside' is a term used for the fitment of a car tyre to a motorcycle wheel.

I have always thought that these projects need either a car wheel fabricated to fit the original swing arm or your own design rear suspension, or use

one of the aftermarket wide swing arms and wheels a la Harley Davidson. Although they are available for other bikes, all be it mainly from the States.

An original R1 190 width tyre looks very puny on a trike.

PS MSVA is £104 v IVA £450

53Stix - 3/2/20 at 04:56 PM

I did know that but only learnt it recently, and by mistake!

The name comes from my surname, Moon, which led me to explore all sorts of similar lunar-based nomenclature. Darkside just seemed to work for me!

I keep playing around with wheel and tyre sizes, but I think I'm fairly well settled on 185/55-13 up front and 245/50-13 at the rear. The more I

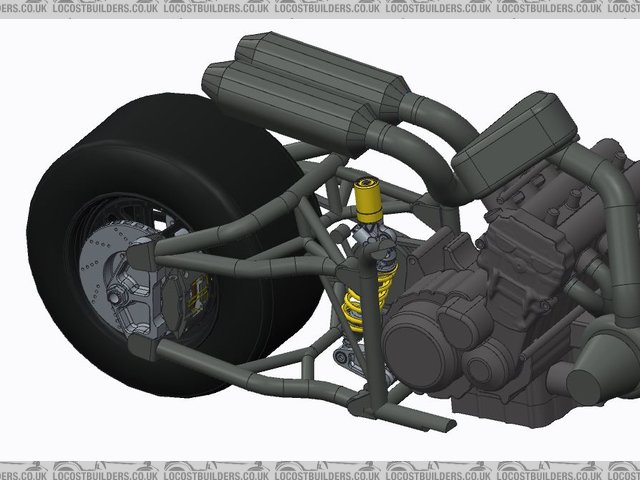

look the more I favour high aspect ratios to try and benefit from the inherent compliance that they bring, and whilst the front wheels will inevitably

be COTS 13" the rear will need to be a bespoke split rim jobby due to the nature of the beast.

I designed an all-electric drag bike a while back which had a very wide split rim at the rear and I was surprised at how cost effective it was.

Description

[Edited on 3/2/20 by 53Stix]

Mr Whippy - 4/2/20 at 06:45 AM

that's cool

watsonpj - 12/2/20 at 04:48 PM

Agree the electric bike is cool any more info on that, I think an electric trike would be great.

Sorry its not the direction of the thread but would be great but harder to register than even IVA I guess.

Uphill Racer - 13/2/20 at 12:38 AM

Did Jo White build the frame for the bike?

53Stix - 13/2/20 at 09:33 AM

Yes, designed by myself and fabricated by Jo of Vulcan.

The project had superb potential to break the world record but sadly the designed of the motor was, shall we say, lacked a little integrity, and the

project seized before we were ever able to run it in anger.

Hence, it's now taking up space in my workshop!

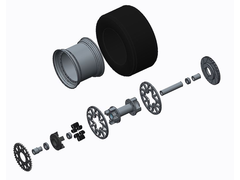

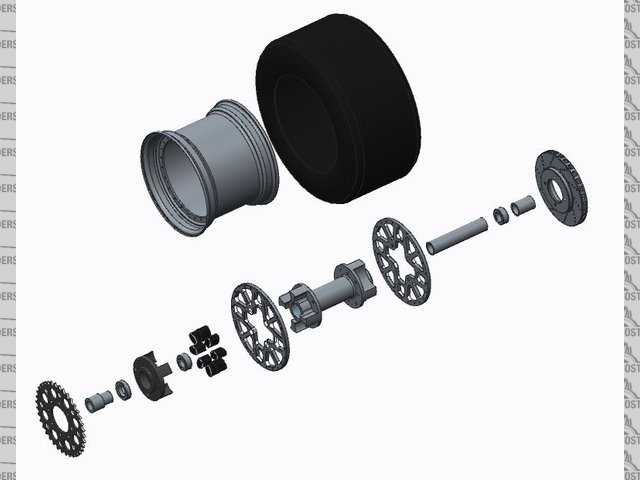

53Stix - 29/2/20 at 03:02 PM

A brief update for anyone that's interested...

Managed to find a few evenings to start focusing in on some specific areas.

Had a stab at a bespoke 13x10.5 rear wheel using COTS parts where possible. Fairly confident the shaft/bearing arrangement works OK, although the cush

drive solution drives a bit of complexity into the design.

Acquired a seemingly representative model of a Powerlite caliper which I've adopted front and rear, and which packages up quite nicely at this

stage.

Also went a bit mad on a fancy front suspension linkage design with ARB that uses Hayabusa taper roller bearings, plus started playing around with

some layouts for forced induction

Next up - chain tensioning strategy and a countershaft of some description, plus need to think about oil reservoir, battery and radiator locations.

Description

Description

Description

Description

Description

Description

[Edited on 29/2/20 by 53Stix]

[Edited on 29/2/20 by 53Stix]

Uphill Racer - 1/3/20 at 09:24 PM

Sorry to hear that you were let down as the bike looked like it had great potential.

When Ian Scott was thinking about building his 4 wheel drive hill climber we had some interesting conversations regarding close coupled rear wheels

with no diff but induced rear wheel steer, a step to far though.

With regard to your front pushrod and ARB system, have you thought about using a third spring and a Tee ARB?

Mr Whippy - 2/3/20 at 07:34 AM

I notice you have not yet included the steering column or rack, how is that going to work? it looks like it will be coming down between your legs?? it

might be worth at some point soon mocking the cabin up out of wood etc just to check the ergonomics of it and whether it is possible to climb in and

out. I'd still like to see some steel beyond the pedals tbh, far too VW camper crumple zone for me.

I build large wooden R/C model aeroplanes and while designing them I will build many mock-up parts to see if they work the way I thought on paper.

Drawings or CAD models are all very well & good but actually having the thing in your hands so you can twist, bash or flex it can't be

beaten.

If I was you I'd get some balsa wood and build say a 12 inch model of the frame for testing. Could save you a lot of time & money later, will

also give you an idea of how much a pain all those joints are going to be

53Stix - 2/3/20 at 09:22 AM

@Uphill Racer - My relative inexperience shines bright here as whilst I've searched far and wide for suspension architectures which meet the

design brief, my lack of experience in four wheeled vehicles means I don't have much in the way of "applied" experience to critique

them over/above perceived mass and cost.

There are some interesting benchmarks buried in the depths of the Spartan build thread...

https://reversetrikes.freeforums.net/thread/102/spartan-trik

e-project-captainamerica

...although if I understand you correctly what you're referring to is primarily a means of controlling heave rather than roll, similarly to the

setup used by Cody Loveland on his original Enviate?

@Mr Whippy - Good suggestion! Steering column and rack are visible, but hard to distinguish in the images above to be fair. Current intention is a

Narrco FSAE rack...

https://fsaeparts.com/products/narrco-racks

...but, again, that's purely on the basis of not having stumbled across anything more suitable just yet. All suggestions welcome!

An ergonomic buck is certainly high on the agenda. I think there's a small number of COTS parts that I want to procure just to get a feel for the

proportions and layout (i.e. wheels, uprights, seat, steering wheel and pedalbox) and then the first job is to lay it all out on the garage floor and

start getting a feel for all these sort of things. You're totally right that you cannot get a genuinely good understanding using CAD alone, and

I'm regularly looking at the tape measure and steel rule on my desk to understand design proportions and clearances etc.

Your earlier comments about crash structure haven't fall on deaf ears - I'm thinking that a front-mounted crash structure again akin to FSAE

designs will be very sensible... I just haven't got round to modelling it just yet.

53Stix - 2/3/20 at 11:42 AM

Just a thought - is anyone likely to be attending Stoneleigh kit car show this year? I'm thinking of pining a Crowdfunder pitch around the time

of the event and am planning to use the show to network and pick up some knowledge on products/services etc. I'd be happy to arrange to some

meet-ups at the event!

-Rob

Uphill Racer - 4/3/20 at 01:06 AM

Yes, but no, Think a little more out of the box than with the Cody set up.

If you move the tee bar to the front of the chassis in the impact zone?

2 birds 1 stone?

53Stix - 4/3/20 at 02:24 PM

Struggling to visualise the setup and how it influences roll stiffness.... any images/sketches?

53Stix - 25/3/20 at 10:00 AM

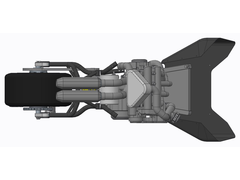

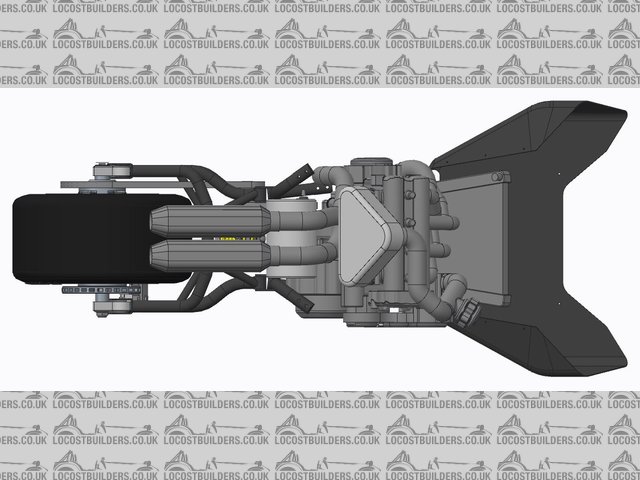

With the requirement to stay at home recently I've taken the opportunity to try and push things forward a little on the design.

Powertrain is coming along nicely. Some very positive input from Richard @ TTS has prompted the move to a supercharger which appears to package quite

nicely.

Description

Description

I've also modelled a simple rad and some ducting which somehow (by accident) seems to remind me of a fish or shark... I like it!

Description

Description

Description

A simple slash-cut exhaust could look pretty cool...

Description

Making good progress now

Description

Description

Description

Finally starting to think about fixturing. The chassis will be a b1tch to fabricate but with only a couple of compound-bent tubes I should think

it's not beyond the realms of possibility.

Description

53Stix - 25/3/20 at 10:32 AM

Here's a couple of shots to show the intended split for the powertrain 'module', which allows the main frame to pick up on the cylinder

head mounting lugs once installed.

Description

Description

And for context, this is a 95th % male in the drivers seat. Snug but hopefully sufficient. Plenty of head clearance in the event of a rollover too.

Description

And finally, speaking of rollover, I've made an assumption for the CoG position and used this to map out the LatAcc threshold (I.e. the angle

made by the cone projecting down from the CoG).

Description

I'm lead to believe that the angle created by the cone when it's tangential to the vehicle contact triangle is a good suggestion (AFAIK) as

to the LatAcc capabilities (i.e. the point at which you'll either roll or slide).

The wider the angle, the harder you can corner, which could be achieved by either lowering the CoG, moving the CoG forward or changing the

wheelbase/track relationship.

The trick is presumably to make sure that you slide before you roll in every scenario... easier said than done I guess!

stevieweavie - 17/4/20 at 07:47 PM

It's worth noting that the above representation of roll over ignores jacking effects of the front suspension and rear swingarm, which tend to

raise the CoG, fluid and driver movement, lateral tyre deflection, and gyroscopic effects of rotating wheels, engine and transmission. These can tend

to have negative effects on keeping the vehicle the right way up. A lot of performance trikes have rolled over in the past. I saw an ultra narrow

rear tracked Formula Student car roll over years ago, inspite of all the calculations they'd done which said it was stable. Same for the Owen

Greenwood trike that raced in the sidecar class in the 60's.

53Stix - 17/4/20 at 08:05 PM

quote:

Originally posted by stevieweavie

It's worth noting that the above representation of roll over ignores jacking effects of the front suspension and rear swingarm, which tend to

raise the CoG, fluid and driver movement, lateral tyre deflection, and gyroscopic effects of rotating wheels, engine and transmission. These can tend

to have negative effects on keeping the vehicle the right way up. A lot of performance trikes have rolled over in the past. I saw an ultra narrow

rear tracked Formula Student car roll over years ago, inspite of all the calculations they'd done which said it was stable. Same for the Owen

Greenwood trike that raced in the sidecar class in the 60's.

Absolutely agree! I'm using this 'rule of thumb' as a guideline when making fundamental architectural decisions rather than anything

else.

The theory should be sound, but I don't believe it'll ever allow me to accurately and repeatably predict a rollover event because, as you

quite rightly say, in reality it's dependent on so many inputs/variables (most of them highly dynamic in nature and almost impossible to define

transiently).

[Edited on 17/4/20 by 53Stix]

53Stix - 5/6/20 at 02:12 PM

Hi all - hope you're keeping safe and well?

A quick progress report on Darkside, as things are moving forwards at quite a rate!

I recently launched drksd.info as means of establishing interest & awareness in the concept. I've

made no secret of my vision to be able to scale up this design to offer a credible/exciting alternative for those looking for a really immersive

driving experience, so this is a vital step in establishing some confidence in the concept.

Thankfully the initial feedback has been overwhelmingly positive, which is really encouraging!

In parallel, I've created social medial accounts on Facebook, Instagram & Twitter... I won't hound you all with requests to

follow/like/share, but clearly if you're interested in the project then it would be worth finding and tagging on to one or more of those

accounts.

Lastly, on Monday I also launched an open design competition, which aims to find a 'look' that aligns to the lean & mean design

philosophy. If it's of interest to anyone, do feel free to get involved - head to

drksd.info/competition to check it out, and also keep an eye on upcoming automotive

press/publications

Best,

-Rob

Description

Description

Solomon - 19/8/20 at 09:22 PM

Hey Rob,

Awesome stuff here. I actually just stumbled on your build thread doing research for the design competition haha. It's really cool seeing hwo

this project has evolved! I'm doing sketches at the moment but I can't wait to throw this into 3D space. I was wondering if you have a .wire

i could use as a skeleton to make sure the body is to proportion? Not sure how strict you want to keep the terms of the comp, but I'd love to

chat about design direction if you're interested. Anyway, hope to hear from you, this thing's going to be a monster!

-Riley

53Stix - 20/8/20 at 07:34 AM

Hi Riley - thanks for reaching out, very pleased to hear that I have your vote of confidence!

As you'll appreciate things have got crazy busy since I launched the website, and moreso since the announcement of FS' involvement in the

Design Competition... >160 Expressions of Interest so far!

In terms of provision of a wireframe or CAD model I'm afraid I'll respectfully decline, for two reasons. Firstly, I'd like to retain my

IP rather than have it out in the public domain, for obvious reasons, and secondly in terms of the design competition it's important to me that

it's offered on a level playing field, i.e. equally accessible to everyone regardless of background, education, or access to specialist toolsets

or software.

I appreciate that the submissions may not be quite as refined but hopefully this will afford everyone the same opportunity to explore their creative

side, and in any case I anticipate that the winning design will need some minor revisions to make sure it's fit for purpose and fully

productionisable etc, which will be done in collaboration with the chosen designer.

In terms of providing commentary on design direction, I'll happily let you know what I think of as good/bad respectively if you were to reach out

to me directly - I would afford anyone the same courtesy - however in the interests of professionalism I'll not be actively guiding designs, if

you know what I mean!

Finally, don't forget that you're free to submit as many entries as you wish, so you could very well submit numerous designs as you see

fit...

Hope this helps, and thanks again for your support!

-Rob

Mr Whippy - 20/8/20 at 08:51 AM

You know I had a problem which I suspect will apply to your trike seeing the wheel selection you have gone for.

I built a beach buggy, a vw based one which was super light, I could pick the front up right off the ground, I'd fitted 225's on the front

as they looked cool but which needed only 13psi to be fully inflated. When I took it for testing it was so lightly loaded, the tyres couldn't

even grip the rolling road for the brake test, the wheels would just stop turning and slide on the rollers. The tester gave up and just took it for a

drive and it passed that way. But stopping it was always entertaining...  really it needed much narrower tyres.

really it needed much narrower tyres.

53Stix - 20/8/20 at 09:29 AM

Hi Mr Whippy - thanks for your insight.

This reinforces the need for a concept demonstrator to iron out all these potential improvements. The spec I've landed on at the moment is a

starting point, but this whole venture is all around credibility and offering a product which not only looks the part, but also performs like nothing

else too.

I've put alot of effort into understanding mass/inertia and positioning, which was instrumental in defining the architecture that I've

arrived at, so once we have a mule vehicle built up we can see if the theory translates into practise! As far as I'm concerned, the need to run

through a robust series of test/configuration/validation exercises is a given... I'd certainly not be willing to put my name to it nor take a

penny of anyone's money until I know it's totally fit for purpose. And, for what it's worth, I'm totally happy to be proven wrong!

:-)

Thanks again - looking forward to being able to update you with progress in due course!

-Rob

Solomon - 22/8/20 at 12:11 AM

quote:

Originally posted by 53Stix

Hi Riley - thanks for reaching out, very pleased to hear that I have your vote of confidence!

As you'll appreciate things have got crazy busy since I launched the website, and moreso since the announcement of FS' involvement in the

Design Competition... >160 Expressions of Interest so far!

In terms of provision of a wireframe or CAD model I'm afraid I'll respectfully decline, for two reasons. Firstly, I'd like to retain my

IP rather than have it out in the public domain, for obvious reasons, and secondly in terms of the design competition it's important to me that

it's offered on a level playing field, i.e. equally accessible to everyone regardless of background, education, or access to specialist toolsets

or software.

I appreciate that the submissions may not be quite as refined but hopefully this will afford everyone the same opportunity to explore their creative

side, and in any case I anticipate that the winning design will need some minor revisions to make sure it's fit for purpose and fully

productionisable etc, which will be done in collaboration with the chosen designer.

In terms of providing commentary on design direction, I'll happily let you know what I think of as good/bad respectively if you were to reach out

to me directly - I would afford anyone the same courtesy - however in the interests of professionalism I'll not be actively guiding designs, if

you know what I mean!

Finally, don't forget that you're free to submit as many entries as you wish, so you could very well submit numerous designs as you see

fit...

Hope this helps, and thanks again for your support!

-Rob

Hey Rob,

Thanks for getting back to me. I had a feeling you'd respond as such and completely understand, people are quick to steal and replicate IP these

days. Would you mind if I built a quick frame model off of your sketches to then model the body over? I promise it will be purely aesthetic.

Unfortunately I'll probabaly be sticking to one design submission as Uni will be starting up shortly and projects are already beginning. I will

however shoot you some sketches and/or renders once things are a bit more refined. What's the best way to reach you?

Glad to hear the project is gaining so much traction and I can't wait to see how it eventually turns out!

Best, Riley

p.s. I'm quite curious about how you ended up linking with FS, if you're keen to share

53Stix - 23/8/20 at 11:20 AM

Hi Riley - thanks!

Nothing stopping you building up your own models etc

Best way to reach me is contact@drksd.info

Frank and I have worked together on some previous projects unrelated to Darkside - I'm very grateful that he's seen fit to support the

design competition!