Ford V6 Engine Mountings

RPS - 16/11/04 at 07:12 PM

Just about to start to fit the Ford v6 in the +4 chassis. Has anyone got any guidance (or photos) on how to build the engine mountings? I seem to

remember seeing somewhere that the offside mounting needs to be lowered to allow the steering column through. How strong does the metal need be to

avoid metal fatigue caused by vibration?

Any help anyone could give will be appreciated.

Thanks,

RPS

Rorty - 17/11/04 at 02:34 AM

I've stuffed dozens of engines into non-standard locations and I find the easiest method is to start with a blank sheet and an open mind.

I simply position the engine/transmission in the desired location, making sure things like the alternator/starter motor etc clears all obstructions.

Chock the engine securely in place with chunks of timber, hardboard, steel or whatever. I then look and see what crossmembers or chassis parts are

convenient to the mounting bracket holes on the engine/gearbox castings. Next, I make the plates that will bolt to the block and attach some short

bits of tube to the plates. These bits of tube are the same as the inner wishbone eyes and will contain two polyurethane bushes and a crush tube. I

orientate the tubes axis parallel to the centreline of the chassis. I then weld a suitable "U" bracket (or two bits of flat bar) to the

chassis to align with the crush tubes. It's then an easy job to lower the engine into the chassis and simply push a bolt through the bracket and

PU bush when the holes line up.

I would use 10mm plate for the engine mounts and 6mm thick flat bar for the chassis mounts.

The PU bushes will last indefinately and provide good vibration absorbtion.

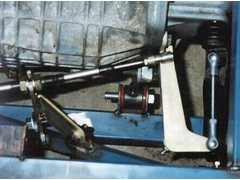

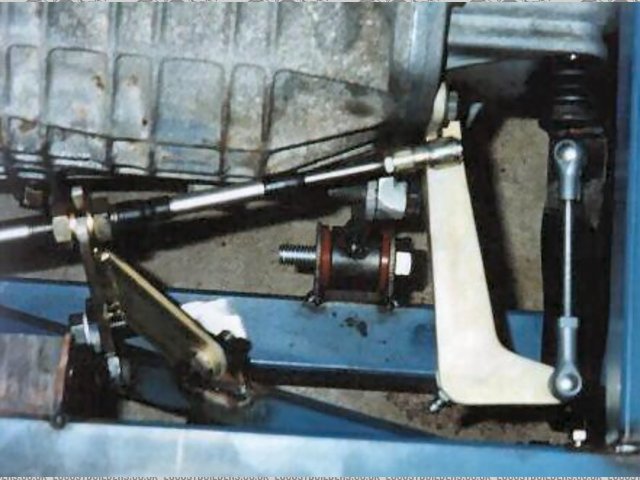

The picture below shows this type of mount used on a gearbox.

Rescued attachment Ren_gear_change.jpg

philgregson - 17/11/04 at 02:18 PM

I have a V6 and started by chocking it in position in the chassis.

I then made a plate for the existing mounting point in the engine and built the mount out and down with 50mm x 3mm wall tube to a plate for the bush

(Fiesta Engine Mount - Rectangular rubber block with a bolt each side).

I then fitted the plate on the chassis and measured the gap between the mounting bush and the chassis mounting point and filled it in with a length of

tube.

Measuring accurately round the engine is difficult and doing it in situ means that it will be accurate.

I used 5mm plate for the engine plate, 3mm plate for either side of the bush and the chassis end and 50mm x 3mm wall tube for the rest.

A couple of points to note:

The steering column - I didn't think about this as I built it (bugger) and it is right in the way - a bit of thought should sort this out for

version 2 (alternatively I may route the steering column over the top of the exhaust manifold).

On the N/S make sure you have the starter motor fitted when you build the mount or you will almost certainly impinge on the back of the motor if you

follow the obvious line.

I am not at the workshop for a few days but will take some pictures when I am next there.

Phil

[Edited on 17/11/04 by philgregson]

RPS - 18/11/04 at 05:53 PM

Thanks Guys. As always, excellent advice.

Phil, the pics of the mountings will be very useful.

Cheers,

RPS

philgregson - 19/11/04 at 12:12 AM

Will try to take piccies his w/e - failed to get to workshop tonight beacuse of snow (which is a pity 'cos my snow tyres are there).

Phil

Chippy - 19/11/04 at 11:44 PM

Hi!, if you have a look at my photo archive, there is a picture of my off side engine mount, which may give you some idea's. This is for mounting

the 2.9i Ford V6. The material used is 3mm plate, and I can assure you that this will be more than up to the task of holding down this engine, if

constructed in a similar way. There is also a picture which shows the steering mock up, this has been routed through three UJ's to avoid the

exhaust, ( yet to be fitted). Hope this helps. Regards Chippy.