First Carbon Fibre sandwich panel made

FuryRebuild - 12/7/13 at 09:29 AM

This post is also at my blog, with better layout.

The original aluminium part weighed 960g, and this part weighs 524g. Thatís a 55% saving in weight.

Description

So, this is my first carbon-fibre part. It is a resin-infusion aramid/foam/glass/carbon part designed to replace a aluminium floor panel. Unlike the

aluminium part which was riveted in, the composite part will be bonded in for good. This will reduce weight and increase rigidity in the chassis. All

in all, Iím really pleased with the result, and the pictures below will show how I made it, and how strong it is.

The layup of the part is:

What Specification

Aramid 2/2 Twill Weave 300g

Closed Cell Foam 10mm

E-Glass 2/2 Twill 200g

Carbon Fibre 2/2 Twill 12k 450g

Epoxy Resin Normal, Slow

Description

Now that the parts are laid on the glass and vacuum bagged, I infused 200g of resin through. Sure enough, this wasnít enough, so I stopped the

infusion process, added another 100g of resin and completed the process. The infusion process slowed down towards the end, and the far-right corner

was the last to fill. Just as the corner filled, I had the input clamp tight, so the corner filled from resin already in the part. I donít think I had

too much resin in there.

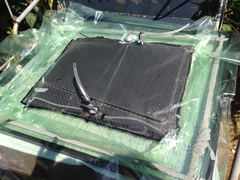

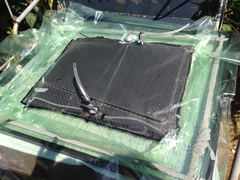

Description

One fully infused, vacuum bagged part, sitting in the sun curing. I was lucky in having to work away from home for three days when the UK weather was

the best its been for a while so the part got a proper baking. For slow resin, 24 hours is a minimum before demoulding, and 36 is better. I got 72,

with three hot blasts of the mid-day sun.

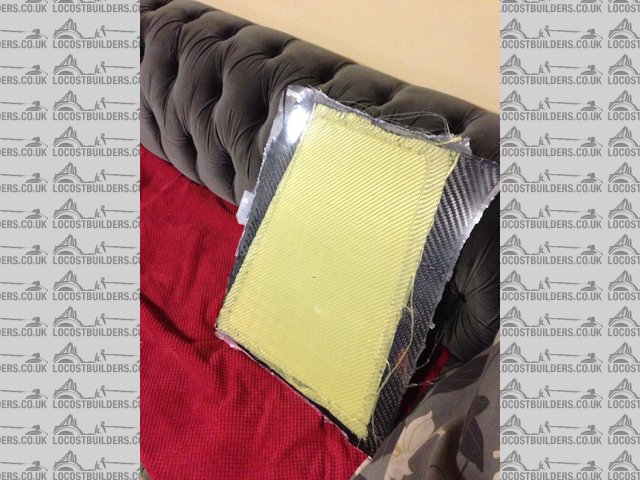

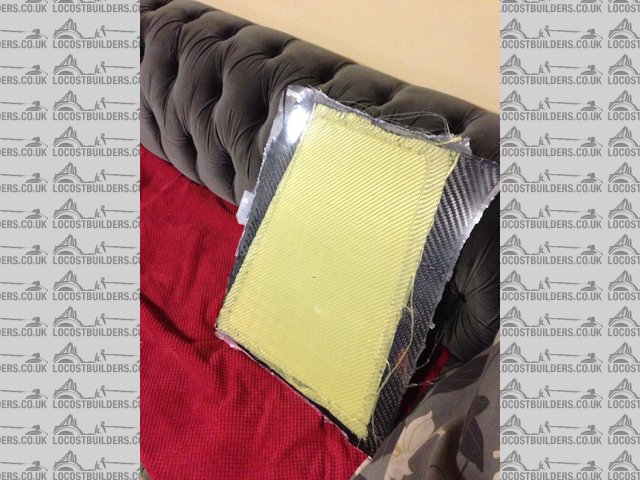

Description

Hereís the part popped from the mound. The easy-lease compound (4 applications, as per the instructions) worked a treat and the part popped off the

glass without a fight. You can see the aramid (yellow), which is the underside part of the car, facing the road surface. Aramid gives brilliant impact

protection. Itís also incredibly strong, and a little more giving than carbon-fibre on its own.

Description

Hereís the side of the part that faces into the footwell. You can see the infusion spiral and resin bung still on the part because I havenít removed

the peel-ply yet that this lot is all stuck to.

Description

Lo and behold it came to pass that the part was peeled and trimmed.

Description

Hereís the finished part, sat on two tins of soup, with my not inconsiderable self balancing on top of it. Note the lack of deflection.

Carbonman - 12/7/13 at 09:33 AM

Get off the bloody forum and get the other panels done Lol

Looks good by the way

omega0684 - 12/7/13 at 09:44 AM

Are you taking orders?

What's panels are you planning to replicate from Ali to CF?

v8kid - 12/7/13 at 10:35 AM

Excellent I'm most impressed - how are you going to bond it to the steel frame and how much weight will this add?

I have tried bonding glass fibre with polyester resin (yup I know its different to epoxy but..) to steel and found that over time the bond fails due

to shear stresses at the join. I always assumed that this was due to differential expansion between the steel and the fibre.

How is this problem overcome? I'm assuming you are going to use an adhesive with some filler in it to fill the gaps hence the question of the

weight of the adhesive. On the other hand there is a weight saving from the pop rivets no longer needed but I can't quite get my head round which

is the greater.

The technique looks stressfull (for the inexperienced operator like me) - do you have time with the epoxy to make changes or does it all happen in a

rush?

Cheers!

David

FuryRebuild - 12/7/13 at 10:41 AM

Hi omega0684

I'm not taking orders  - far too busy with other things as well. If you need help, see Warren (CarbonMan) on here.

- far too busy with other things as well. If you need help, see Warren (CarbonMan) on here.

I'm going to be replacing every non structural steel or ally panel and bond the new carbon panels in (using a special loctite adhesive designed

for the job).

Thanks

Mark

coyoteboy - 12/7/13 at 10:53 AM

Nice, interesting to do the layup as one. I've been involved in the making of a few carbon/foamcarbon kiteboards - these were wet layup and then

vac-bagged as opposed to infusion. I never quite trust infusion but probably should!

Other option is you know you can buy 8x4 carbon/honeycomb/carbon panels off the shelf in various thicknesses?

Lovely to be ablet o make the part exactly as you like it. I was considering making some structural parts of my chassis from this technique but

I'm not sure I trust my construction skills in such a situation.

minitici - 12/7/13 at 11:00 AM

looks good.

I was thinking of making a ballistic shield, for my clutch housing, using aramid cloth layups.

My clutch is going to be right next to my thigh on my 750 Trophy racer.

If that lets go at 8000 rpm it could be a little messy.

RK - 12/7/13 at 11:26 AM

Nice work!

Want to make one of these for my Van Diemen Sports Racer, which currently has a steel floor. Winter project...

[Edited on 12/7/13 by RK]

coyoteboy - 12/7/13 at 11:58 AM

How are you going to estimate the layup required, or are you going to just provide something to help?

snakebelly - 12/7/13 at 12:25 PM

Have you remembered to seal the edges post trimming, when i sid my similar panels i used a dremel to "route" a slot in the permiter the

filled it with aixture of resin and a bulking agent. That way the cut foam edge cant be used as as an entry point for moisture, ating with composites

is fun is t it. We used the hammer trst on our saples and were very impressed

FuryRebuild - 12/7/13 at 02:41 PM

Hi V8kid

I'm intending to use Hysol Loctite EA 9394. It's specifically designed for the job and cures in 2h at room temp. Both sides need to be

keyed, and I'll be doing that by having the chassis sand blasted, and the peel-ply side of the flange is already a perfectly keyed medium.

I'll degrease with either panel-wipe or acetone.

Coyoteboy - thanks for the suggestions for the panels - I knew I could do that, but I wouldn't have had the panels with the mounting flange, and

also I did this for my time and the base costs.

SnakeBelly - please see the photo below- the part runs down from the sandwich panel into a mounting flange. It will be bonded both on the sandwich

side and the flange (from below). The sandwich part of the panel is runs a 1-2mm relief all the way around between the panel and the chassis, which is

about the right amount for the adhesive.

And thanks all for the encouraging comments.

Mark

Description

FuryRebuild - 12/7/13 at 04:11 PM

I'm wondering how to make a prop-catcher at the moment ...

quote:

Originally posted by minitici

looks good.

I was thinking of making a ballistic shield, for my clutch housing, using aramid cloth layups.

My clutch is going to be right next to my thigh on my 750 Trophy racer.

If that lets go at 8000 rpm it could be a little messy.

snakebelly - 12/7/13 at 06:35 PM

ahh I see, we just made oversize sheets so we could use it wherever we wanted rather than making individual panels hence we had to seal the edges once

cut to size.

I admire your trust in adhesives but personally we used PU adhesive and rivets still as there isn't an adhesive made I would trust in this

application given the movement in the chassis and vibration!

atm92484 - 16/7/13 at 02:03 AM

Nice work on the panel - it looks really good.

scudderfish - 16/7/13 at 06:19 AM

How much in materials does it cost to make something like that?

Regards,

Dave

FuryRebuild - 18/7/13 at 08:15 AM

Hi Dave

I recon about £35 to £40 quid but haven't fully calculated it by the cm2 and not including my time and the wastage in learning the pleating,

bagging techniques.

quote:

Originally posted by scudderfish

How much in materials does it cost to make something like that?

Regards,

Dave