Chassis welding that wasn't in the book?

jps - 25/2/13 at 10:39 AM

I've asked the same question over on the Haynes forum specifically but thought i'd try here too (not sure how different the Haynes and

Locost chassis are)...

Has anyone got tips for anything they've welded in that WASN'T in the 'book' design?

Outside of the main structure of chassis rails/suspension mounts, steering rack frame and bulkhead panels I have:

roll bar stays

cross members for seat runners

handbrake cable backplate

handbrake cable mouting plates

'perforated' 3x25mm strip down the tunnel for pipes/etc

gearbox mounts

engine mounts

radiator mounts

steering column frame

cross member for pedal box

harness mounts

I'm wondering if its worth sticking a few 3mm plate sections on the inside of the to chassis rails in the engine bay just in case i need to mount

brackets later on, i.e. for the horn, the coil, the coolant header tank, etc, etc?

At the moment i have no idea where these parts (and probably others) will be mounted - but I don't want to get the car 90% built before painting

the chassis...

So far the suggestions i've had are:

prop catcher (don't think i'll bother - seems like overkill to me?)

tabs for earth connections (think i will bother!)

James - 25/2/13 at 10:52 AM

Once you've seen some pics of what an errant prop can do to the inside of you tunnel (to fuel lines, electrics, brake lines etc. etc.) you may

not think it over kill.

I had to bolt mine in as it was after the car was SVA'd that I got concerned.

Starting again I would weld the top hoop in and probably bolt the lower hoop.

HTH,

James

pewe - 25/2/13 at 11:55 AM

Totally agree with James ^^ IIRC there was someone on here or a Locost racer who had his thigh slashed severely when the prop let go.

If you are only painting the chassis then second-guessing bracketry position isn't such a problem compared to it being powder-coated.

Paint can always be scraped back to allow welding and re-painted.

On mine I added brackets post build for the horns, oil cooler, fuel regulator and dzeus fasteners for the bonnet.

Having listed those I suppose a lot depends on what engine/ engine bay set-up you have which will dictate bracket positions.

Cheers, Pewe10

40inches - 25/2/13 at 11:55 AM

Prop catchers are a must, do a search, not that rare for a prop to let go.

You don't need to weld them in, bolted is fine.

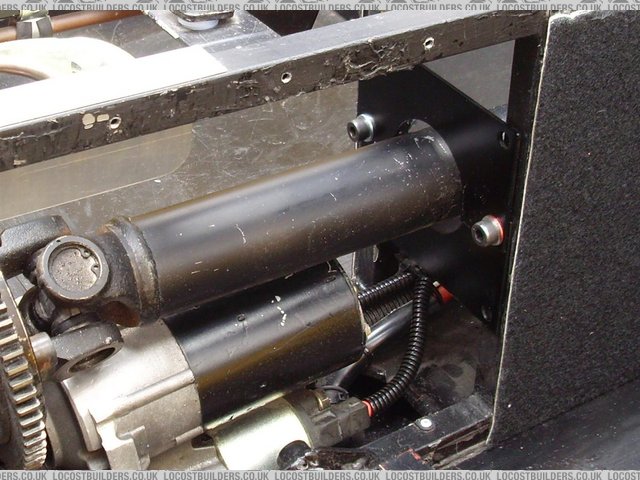

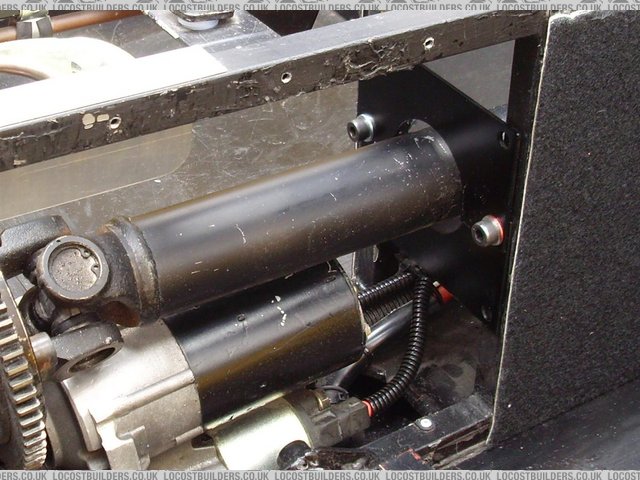

Prop Catcher

40inches - 25/2/13 at 12:10 PM

The case for prop catchers and fire extinguishers. thread

iank - 25/2/13 at 12:25 PM

Another photo showing a prop having thrashed it's way through the tunnel

http://www.locostbuilders.co.uk/viewthread.php?tid=122181

jps - 25/2/13 at 12:36 PM

Given i'm only going to run a 1.6 Pinto with 70bhp, and i'm going to have the prop made for me rather than try and DIY, i'm still not

sure a prop-catcher will ever get pressed into service.

HOWEVER - having scanned the links above i am definitely going to fabricate one for each end and fit them...

I was already sold on the idea of a fire-extinguisher!

[Edited on 25/2/13 by jps]

snapper - 25/2/13 at 03:37 PM

Your 1.6 with 70bhp will soon be upgraded trust me

I have a steel tunnel but put thicker steel plate inside for peace of mind.

You'll never know if you need it......until you need it

Confused but excited. - 25/2/13 at 04:18 PM

A prop catcher is only overkill, if you haven't experienced one go.

My Locost will only have a 1300 X-Flow in it, it will also have a prop catcher, trust me.

It happened to me in the early 70s and I have never forgotten it!

NOT something I want to experience again, talk about a brown touser moment.