I was looking last night at making up a couple of brackets to hold my main lights. What type of bracket is most widely used i.e. angle, tube, box

section?

Also, at what point on the chassis should the bracket be fixed to ensure compliance with the SVA, in terms of visibility?

Any help or pictures appreciated.

Cheers.

i used 6x25mm flat bar, welded onto the top chassis rail. not sure of compliance etc cos it hasnt been tested yet.

a nice bit of oval tube should comply and look nice too if you can get it

ONe thing i thought of was a one piece round/oval tube going from the left to the right of the whole car. Mounting the lights onto this and then

mounting it to the chassis using brackets so it can rotate along its axis(once the brackets are loosened) this allows you to quickly change the angle

of the projected light at SVA.

good idea???? comments.........

dont most stand alone hedlights have a ball type joinr on the bottom anyway to allow for adjustment in angle/direction?

If you used one bar across the whole of the car then you couldnt adjust the lights individually in the vertical plane - just a thought

I just cut and welded a piece of box section for mine, just necessitated another cut out in the nose cone.

headlamp trail 02

[Edited on 22/9/04 by scutter]

Thanks for the suggestions. I was trying to think of some way of avoiding cutting notches in the nosecone, as it is bound to cause unwanted stress

points in the GRP. I will probably just have to cut the notches though as there doesn't appear to be an alternative.

I will go for either the square tube or flatbar, as i have the materials, oval tube would be nice, but i dont have any and i dont think it will be

readily available in my area.

How easy is it going to be to get the necessary radiuses on the ends of the brackets and the screw part of the mounting, or how can they be covered up

for the SVA?

I mounted by front indicators last night and welded them to the chassis,i was feeling quite happy cos they looked good and complied with the SVA

manual, then i realised that they are fouling the cycle wings on full lock both sides

Looks like the grinder might have to be brought out of retirement again!!

I have realised that the further you get with the build the more things there are to grind off and move!!

If you want to avoid cutting notches in the nosecone, just weld the supports directly on the outer face of the chassis.

I did it half and half, but the theory still holds up

Rescued attachment Headlamp Brackets.jpg

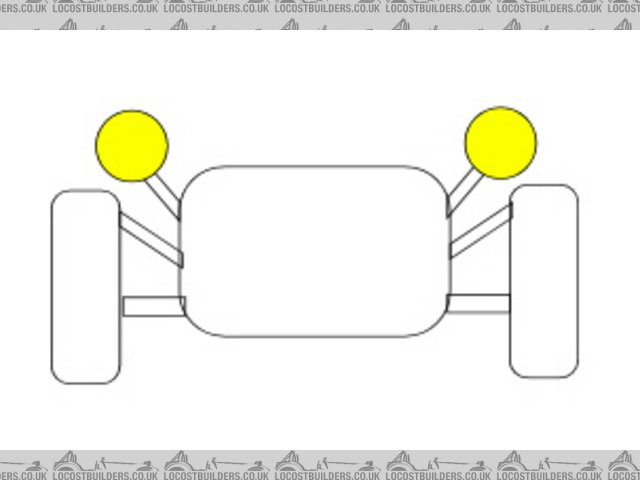

I'm going to weld mine to the outside of the top rail. Cut it at 45 degrees so it goes up high enough and mount it in the centre of the wheel so

it doesn't get to foul. On my first one I used flat bar 5mmx50mm but I had to put upstands on to get the height

[Edited on 22/9/04 by Peteff]

Rescued attachment lamps.jpg

Albertz,

Don't know if you have your nosecone yet but most I've seen (GTS, MK etc.) have the cut out moulded into the 'cone already.

HTH,

James

James,

Those lowline locost noses are pretty mch all moulded off a caterham. The bit you refer to is too far back and most use it for routing a cable in a

plastic wrap/shower hose type tube. I'm going to weld tube to the outside top chassis rail at an angle as already described..

Ned.