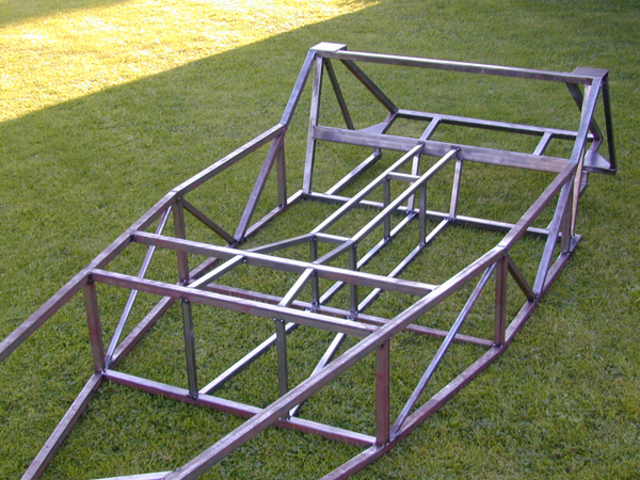

Rescued attachment tran_tun.jpg

I've read a few post and have found a few which refer to using a type 9 in a book chassis, which is good as that's what I intend to do. Can

anyone highlight and dos and don'ts as far as positioning the box goes and anything else that might be of benefit. I have all the steel for the

tranny tunnel sitting on the drive and have the next week off. I'm dying do get it done as the next step for me will be the wishbones and de

dion.

Any general comments very welcome.

Cheers guys,

Chris.

You will find that the back end of the bellhousing won't go down the transmission housing, unless you make changes to the chassis - which would

mean less foot space.

I mounted my x-flow and type-9 box so that the back of the bellhousing is about 5-10mm away from the chassis upright. This seemed to work very

well.

rgds,

David

Don't let the end of the gearbox coincide with any of the uprights - I did and am having real troubles with the box fouling brake pipes, loom,

fuel pipes etc.

The end of the box is about 3 1/2" wide and the tunnel is 4" wide inside of the uprights, that leaves 1/4" either side, not including

any movement of the box in motion.

Put the box in the chassis and build the tunnel round it. Put a piece of board in with clearance for the gearbox and see how much room it leaves for your feet . Watch out for the clutch actuating arm, leave room for it and don't block its movement.

Cheers guys. Hopefully gonna get started tomorrow. Have spent the day fitting a tow hitch as I need the trailer to pick up another 8' x 4' board to work on. The last one suffered a bit of water damage. Thanks again.

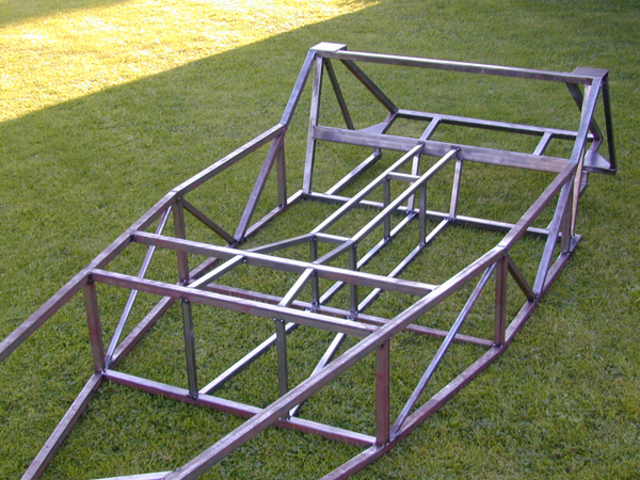

Went book for the bell-housing and kinda made up the rest. Feels really good to have an idea of the cockpit size and it's starting to feel like a

car... with substantial parts missing.

Rescued attachment tran_tun.jpg