Cad drawing of chassis

malcolmstoddart - 2/8/04 at 08:52 PM

Guys

I have put first couple of my cad drawings in my photo archive for your comments - thoughts, I better explain, I used Terrapin_racing (thankyou!!!)

for inspiration here (http://www.locostbuilders.co.uk/viewthread.php?tid=11864) with two bulkheads welded together around the circumference and in the

big gaps as shown in cad drawing, these bulkheads are separated by steel tubes which locate the main chassis rails a set distance apart, I have made a

few trial runs of the bulkheads and tube format - and everything seems ok, plan to weld up fully one complete unit and subject it to some tests and

see how it performs in the meantime can you's have a squint and see what you think....

in the meantime can you's have a squint and see what you think....

Cheers for now

Malcolm

ned - 3/8/04 at 08:12 AM

I like the idea of using sheer plates, it makes the chassis nice and easy to assemble and it can be split easily to. I would think you'd need

more triangulation in the bulkheads and the supporting members, though guess this is an early drawing so these triangulation members may be yet to

come.

Ned.

ceebmoj - 3/8/04 at 11:08 AM

I think it looks nice however for the roll over bar how will you stand with any form of scroutenering if you deside to take it on to a track?

blueshift - 3/8/04 at 04:52 PM

I assume there's going to be some kind of triangulation? it doesn't look very strong at the moment.

note, I'm not an engineer.

derf - 3/8/04 at 06:59 PM

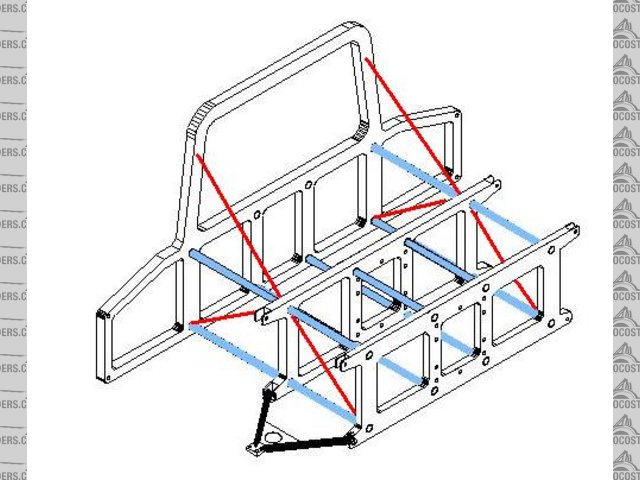

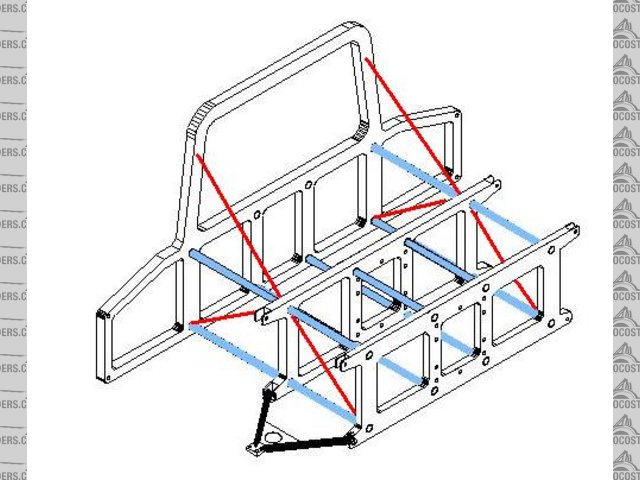

I added some x-bracing that would make the frame much stronger, From the looks of it you will be having your frame made from solid machined plates.

While this is a good idea, I dont believe that it is the most prudent way of building a car. Let me explain:

1. The cost of buying and machining the plates will have to be expensive, unless you do it yourself, and thats a butload of work, and expensive

equiptment, and I'm sure it's still more than just building a spaceframe.

2. Weight, hollow steel tubes weigh alot less than a solid plate, and can be stronger, and easier to build with.

On the plus side, I do belive that it is a good Idea, if modified, would it be possible to use the bottome half as a plate, have a roll bar on top,

and have the diff mounted between smaller plates with the suspension mounted to the spaceframe.

My additions to the frame to make it stronger:

Description

New rear end design:

Image deleted by owner

Now again, I think it's a great idea in theory, just needs some modiication to make it perfect.

ceebmoj - 3/8/04 at 09:13 PM

if you look at the second dawing is shos that the sections are made from thin sheat held to dether with edjing and tube through conectors

blueshift - 4/8/04 at 01:09 AM

Looks very pretty but a lot of work, and I don't see where the strength is.

Piledhigher - 4/8/04 at 07:32 PM

While not necessarily locost, I love the idea of making these bulkheads. You can have the sheets laser cut by emachineshop.com for a nominal price

and weld the outer strip yourself.

I am planning a frame with significant deviations from the book and am seriously contemplating this method.

Cory

malcolmstoddart - 4/8/04 at 09:51 PM

The main bulkhead panels are made from 1mm sheet steel (or will be if I go down this route) laser cut by a company in Glasgow, Ceebmoj got his done

there and the finish is second to none and requires NO final finishing..

As for bracing I have contemplated following the theme of the bulkheads right round the rear of the chassis and missing out the tubes altogether,

just a thought..

Roll bar.. I put this in square section there because at that time I couldn't figure out how to do the 90 degree (or so) turn at the top in

tubes in autosketch when working in the 3d manner (all help please )

)

I plan to make up one shortly and subject it to some tests, possibly external testers we use at work..and will see how it performs then against

steel tubular format.

will modify it soon and repost it then

cheers for now..

Hugh Paterson - 5/8/04 at 08:00 PM

Ooooooohhhhhhhhh so now we know ya crafty git, think Stevie boy and I are going to Knockhill next week if your doon this neck of the woods Malc will

confirm when I know the details.

Cheers the noo

Shug.

in the meantime can you's have a squint and see what you think....

in the meantime can you's have a squint and see what you think....