Don't argue with trees....

pewe - 2/5/11 at 09:45 AM

Due to an unfortunate coming together (not me I hasten to add) with a tree yesterday the front end of the F27 is now FUBAR.

At first inspection it looks as if it's stuffed the front section as far back as the lower suspension arm pick-up points without damaging the

major mechanicals.

The upper and lower side rails ahead of the engine have been bowed in as the tree was hit dead centre (what's that about driving for the escape

route?).

Question is whether to cut out the mangled section and graft in new 25mm SST or replace the whole chassis.

I'd prefer to do the former but what's the best way to join new tubing to old - square joins, angled joins, plated joins, sleeve inside and

rosette weld before surface welding or ANOther?

Having never been down this road before your advice appreciated.

Also anyone local to Reading have any decent 25mm SSQ tubing in exchange for beer tokens?

Cheers, Pewe.

blakep82 - 2/5/11 at 10:43 AM

if replacing tube, i'd replace WHOLE tubes. can't think of how to explain this one, but I wouldn't cut a damaged tube in half, and then

extend it.

edit:

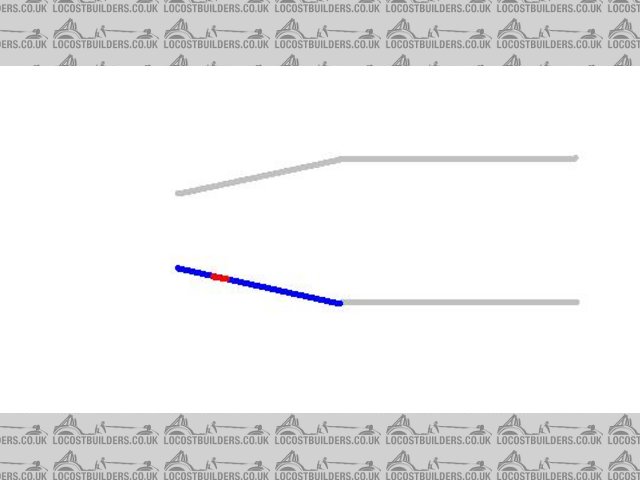

if your chassis is damaged where the red bit is, replace the whole tube marked in blue. i wouldn't cut out the damage and only replce that

Description

thats how i'd do it

[Edited on 2/5/11 by blakep82]

david_hornet27 - 2/5/11 at 11:22 AM

Have a bit of 25x25 in the garage. U2U sent...

mark chandler - 2/5/11 at 12:51 PM

Try and bash the bent front back to where it came from, then cut out and replace the ruined tubes.

I would start off measuring diagonals to see if its twisted first, nothing wrong with replacing elements if the rest is straight.

Mark Allanson - 2/5/11 at 01:17 PM

I tried to google this to save me typing it all out but alas no joy. You need to do a drop check.

1, strip out the front end to bare chassis

2, put the car on 4 identical axle stands on level ground

3, get a plumbline and mark the undamaged area on the chassis onto the ground using masking tape and a sharp pencil (so the undamaged area can be

mapped onto the floor as a series of dots on the floor)

4, get some fine string and coloured chark, 'soak' the string in the chalk and tensiion the string over the dots, twang the string and this

will give a straight line between the dots, do the diagonally and straight so the centreline can be established.

5. twang the string over the convegent diagonals to mark the centreline

6, Repeat the above on the damaged area to establish how bent the frame really is.

7, If pushed over to one side, remove an obviously damaged rail and pull the chassis back into line and then replace the rail with new.

Weld up using the exact method used in the initial manufacture

This is how all cars were repaired before the advent of chassis jigs, some shops are still using it!

Canada EH! - 2/5/11 at 02:58 PM

If you can get hold of a port-a-power, try to straighten the chassis, then cut off the offending parts and replace, going back to the next weld

point.

Make sure all is square before welding on the new section. The damage may be further back than you see at first light, the reason for get the bent

chassis close to square before you start to rebuild.

pewe - 2/5/11 at 06:04 PM

Thanks guys. Will finish off stripping back and then take some measurements.

B*gger of it was it was an Autosolo and I was marshalling just behind the tree where he parked it.

You know that feeling you have when it's all in slo-mo - it was even worse watching your own car in the process of having an accident that's

not your fault.

Take my advice don't lend your kids your car!

Cheers, Pewe.

Good call hicost V - was impressed by their friendliness/service when I bought some Protechs from them recently.

[Edited on 3/5/11 by pewe]

hicost blade - 2/5/11 at 07:29 PM

Pro Comp www.procomp.co.uk fix this kind of damage allllll the time

If I were in your position I would be on the phone to them without hesitiation

Krismc - 4/5/11 at 06:51 PM

Least the youngen is ok, and now knows what understeer is