Was looking for a thread to refer you to, but am having no luck with the 'search' button today. Hopefully, someone who has done this will pipe up

Pete

Its been disscussed alot but has anyone used 18 awg for the floor sheeting and do you have a problem with oil canning/ popping when you get in and out

of the car.

Thanks

Dale

Just from my limited experience, I get that with a 16 guage floor, fully welded, not bad, but it does make a slight pop sound once in a while when I get in/out, I'm sure it would be worse with an 18 gauge floor. The weigt difference shouldnt be too much eith, maybee a few pounds, 10-15?

If you have lengthwise beads rolled into 18 awg, you should have no drumming.

Was looking for a thread to refer you to, but am having no luck with the 'search' button today. Hopefully, someone who has done this will

pipe up

Pete

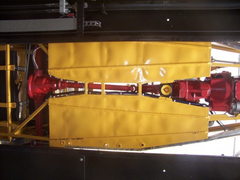

Cant remember what guage i used, but i braced it with 10mm square tube

Click Me

I used 18g, braced underneath and angled to make sure there were no symetrical areas of steel left to harmonise with certain engine revs - I HATE that

metallic rasp of vibrating sheet steel.

I used 13mm ERW 16g box to brace

Rescued attachment Underneath.jpg

quote:

Originally posted by pbura

If you have lengthwise beads rolled into 18 awg, you should have no drumming.

Was looking for a thread to refer you to, but am having no luck with the 'search' button today. Hopefully, someone who has done this will pipe up

Pete

Mark, in your photo of the floor of your car showing your bracing, what are the round bits near the side for??

just don't use a 12 guage - you'll blow your nuts off!

Thanks for the info, being I am 245lbs 16 gauge may be more suitable with the bracing as well., I plan on welding in the tunel sides as well. What

are the opinions on how 18-16 gauge will hold up to broken or propshaft or exploding transmission. I have seen the pics of the damage on one done in

alloy, and that did not make me feel very safe as I should eventually be pushing somewhere between 225-300hp.

Thanks

Dale

Hmmn, the Locost racers have to add an additional diagonal to protect themselves from a potentially flailing prop -- seems a good idea to me (as well

as a mirrored tube to protect the passenger in a road car). A prop wagging about would make a marvelous "can" opener and steel sheet,

regardless of guage, is not terribly resistant to tearing.

On the other hand, if your prop tears one cheek off you'll be able to hang out with all of the gimps at the motorcycle races...

Cheers, Ted

quote:

Originally posted by kiwirex

Mark, in your photo of the floor of your car showing your bracing, what are the round bits near the side for??

Yes, they are drain holes, M20 heavy washers continuously welded into the floor in the corner of every sealed area. having no roof I expect the car to leak a bit !

Hmmm, you've made me worried I need to go drill some holes in my floor now!

One reassuring thing though Mark- your floor is a ripply as mine! It took me ages to get that special aerodynamic effect though!

James

For welding in the floor, have most gone for stitch welding it in first and then full weld the entire thing in or to drill the floor similar to

riviting it in but then plug weld it in by welding through the holes?

Thanks again.

Dale

i stitched mine, then did it full. I like the idea of using thin guage with creases in it. mine is 16g, the sides 22g. with fully welded transmission

tunnel sides.

M20 heavy washers continuously welded into the floor

Is global warming really having that much effect down your way ??

I'll go for 3mm holes in the floor, rain up here is quite thin, if persistant.

Mick