Rescued attachment 138-3801_IMG.JPG

Rescued attachment 138-3801_IMG.JPG

wikid!!!what engine is that?

quote:

Originally posted by theconrodkid

wikid!!!what engine is that?

so what transmission then and where does it get its drive from,look even better with a blade in it

Honda 500 cc dirt bike engine-50+ HP

Diff from Mercedes 190.

I'm abit confused, the engine looks like it's mounted inlet (or exhaust) fore and aft. Surelu the drive is from the side of the gearbox ?.

How is it coupled ?

P S, It's Rotax

Diff is to be rebuild to take sprocket and chain.

Engine is mounted as it would be on the bike.The carb is not on hence the big hole witch misleadingly can be seen as the exhaust.

infinit improbibility drive?

What you mean by "infinite improbibility drive"?

Is it a CR500? That's sacrilage breaking one of those to make anything else. They should be preserved for future generations to see how mad the 20th century was and how people had no regard for personal safety, voluntarily hurling themselves into oblivion on these projectiles.

cita,infinite improbibility drive was in the hitch hikers guide to the galaxy series,look it up,read the books by douglas adams

Yep! Honda CR 500

Purchased it some 10 years ago and took it apart for one of my crazy helicopter projects.

Made one ride on that bike and that thing scared the hell out of me.

Really confused now, if its from a CR500 it must be an ancient one as it is obviously air cooled. It's not a Rotax then as they are four stroke

in the large cc versions. Yours is a two stroke I assume.

Me thinks you will have much fun with burning clutches due to high revs required due to low torque. But if it works for you, hey, go for it !

I too am a little confused (not difficult)

CR500's were strokers, that certainly looks like a Rotax engine and rotax do make 2 strokes but I dont recall a CR with a rotax. Are you sure its

not from a CCM?

Like the look of the chassis, pretty close to what I'm working on for my next project, But I was going sand rail route.

Reckon you will have drive problems with the engine being gutless below 7K and a very narrow power band.

Also will kicking it into life be practical when you are gonna be stalling a lot.

I love big singles I own a XR650R racer,

personally I would give serious consideration to using a Honda XL650 or Dominator, both have leccy boot.

Or as a great compromise, a Yammy TDM/TRX 850. Really compact parallel twin and comes ready dry sumped.

Interesting project Cita, keep us posted.

John

Two stroke it is from Honda.

I hope that the low weight of the car(should be less than half of a locost)will be gentle on the clutch,if not than i will have to build a lighter car

is'nt it?

Something as a Lotus 18 lookalike

Definitely daring to be different.

After riding motocross for some years I always fancied a motocross engined road bike or a motocross bike made road legal.

This is the first time I've seen a motocross engined car.

CR500 was from back in the day when we had a world champion at THAT sport aswell. Dave Thorpe, I believe.

Cita, at least you didn't chose a CX500, yuk.

Good luck with your project, how did you plan on a starting mechanism ?

I seem to remember there being a 'de-compression lever' fitted on the bars of the bike and a kick start that could break your leg if you got

your timing wrong.

I am afraid no de-compression mechanism.Kick start can brake your ankle without any problem on these monsters.

Starting will be by means of pushing the car with me in it and two nice blondes pushing

OK, back to the chain drive thingy....

I'm trying to picture this: Are you intending to attach a chain sprocket to one side of the diff? Inboard of the inner cv joint? Will this leave

the (now unused) input shaft free-spinning? Will this provide power to the other wheel? Pardon my lack of understanding.

I assumed Cita will adapt the diff input shaft to accept chain drive (weld a sprocket onto it) Driving one of half shafts will only drive that wheel.

If the prop input was 'locked' the opposing wheel would drive the opposite way.

John

quote:

Originally posted by spunky

I assumed Cita will adapt the diff input shaft to accept chain drive (weld a sprocket onto it) Driving one of half shafts will only drive that wheel. If the prop input was 'locked' the opposing wheel would drive the opposite way.

John

) and the sprocket is on the right side, not facing out the back.... in that configuration it'll never drive the input to the diff

with a chain. Hence the 'Improbability Drive' quote earlier?

) and the sprocket is on the right side, not facing out the back.... in that configuration it'll never drive the input to the diff

with a chain. Hence the 'Improbability Drive' quote earlier?

quote:

Originally posted by sgraber

quote:

Originally posted by spunky

I assumed Cita will adapt the diff input shaft to accept chain drive (weld a sprocket onto it) Driving one of half shafts will only drive that wheel. If the prop input was 'locked' the opposing wheel would drive the opposite way.

John

Well that's what I thought! But Cita mentioned above that the engine was in place the way it would stay. I have ridden the CR500 (it's a good ride...) and the sprocket is on the right side, not facing out the back.... in that configuration it'll never drive the input to the diff with a chain. Hence the 'Improbability Drive' quote earlier?

OK maybe not.

OK maybe not.

.......................

.......................

.................

.................

thats why i mentioned infinite inprobility drive,just a hot cuppa and a few wires,simple

Looks pretty obvious to me, if you look at the diff housing it's already had the back (and presumably the front) section chopped off. The

sprocket will be attached to the crown wheel with a chain drive direct to the bike engine, no bevel gears in sight.

The interesting bit will be keeping the diff lubricated...

quote:

Originally posted by MikeRJ

Looks pretty obvious to me, if you look at the diff housing it's already had the back (and presumably the front) section chopped off. The sprocket will be attached to the crown wheel with a chain drive direct to the bike engine, no bevel gears in sight.

Mike

Thats really got my interest, lubrication issues aside, has this been done successfully before?

The interesting bit will be keeping the diff lubricated...

Just a thought - if you bolt a sprocket onto the diff in place of the crownwheel, you can turn the diff round so the 'back' becomes the

'front' and simply remove the pinion & its bearings & stick a cork in the hole! The diff can be upside down, back to front, it

doesn't matter, it will always turn the wheels in the right direction. Without the pinion there are no issues wrt drive direction.

cheers

Bob

keep it simple guys!

Rescued attachment chain2.jpg

quote:

Originally posted by spunky

Mike

Thats really got my interest, lubrication issues aside, has this been done successfully before?

and

Rescued attachment chain1.jpg

quote:

Originally posted by Terrapin_racing

keep it simple guys!

The diff has it's front chopped off and is turned back to front.The crown wheel will be replaced by a sprocket and the diff will keep all

it's advantages.

Since i intend to use the car in hillclimbs the runs will be short so lubrication,as Rob (Terrapin) suggested will be with super sticky lubricant.

quote:

Originally posted by Cita

The diff has it's front chopped off and is turned back to front.The crown wheel will be replaced by a sprocket and the diff will keep all it's advantages.

Since i intend to use the car in hillclimbs the runs will be short so lubrication,as Rob (Terrapin) suggested will be with super sticky lubricant.

Thin sheet metal-polyester-aluminum you name it.

I'm thinking about this Steve and it would'nt be a difficult thing to do.

The problem is not the backside of the diff but the side where the chain comes out the diff and goes to the engine sprocket.

quote:

Originally posted by Cita

Thin sheet metal-polyester-aluminum you name it.

I'm thinking about this Steve and it would'nt be a difficult thing to do.

The problem is not the backside of the diff but the side where the chain comes out the diff and goes to the engine sprocket.

That's a very good idea Steve!Thanks!!

You could use a Scottoiler and adapt it to lube the chain and planetery gears at the same time.

John

I've seen CR500 engines in cars before, though ususlly the later water cooled versions. I used to race against quite a potent CR powered car.

You'll need to keep the weight below 350 kg or it will eat clutches/go nowhere. It's not an ideal engine for a hill climber though: you need

torque for pulling out of tight turns etc. Make sure the gear stick is well oiled. It'll be seeing a lot of action!

That's an unnecessarily complicated diff arangement, and I wouldn't use any "super sticky lubricant" as it will rob the engine of

much needed power. Keep even light oil out of it other than a preliminary squirt on the bearings. Use dry film lubricant on the chain to prevent dirt

and grit sticking to it.

I've got to ask: why use a diff at all. With a very light chassis and low COG, it's not much more than a glorified go-kart. I would be

inclined to run a solid/locked axle and let the engine and tyres sort it out amongst themselves.

I've also seen an on-board starter using a chain, sprocket and hand-operated lever (more weight though).

Push starting sounds fine for hill climbs. There are always plenty of eager suckers around the pits.

Buy a high quality "O" ring type chain.

No need for any chain oil at all........

quote:

Originally posted by Fifer

Buy a high quality "O" ring type chain.

No need for any chain oil at all........

quote:

Originally posted by Fifer

Buy a high quality "O" ring type chain.

No need for any chain oil at all........

I'm sure someone mentioned above lubing the chain !

Sorry for commenting

How much power does an O ring chain take over a normal one ?

I'm guessing you would be pushed to see the diference on a dyno ?

For what it's worth, if it's for racing, I would go with the locked diff set up, i used to weld up my diff on my stock car as it's not

required when you are sliding in every corner.

Hey Ho, better not get involved

Your right, sealed chains dont rob much and hardly worth bothering with on a 180bhp superbike, but on a low powered competition machine it's

gotta help.

I use plain chains on my enduro, not for power but sand under the O rings shags them pretty quick....

John

On lubricating a chain driven diff -- why not use a viscous LSD mounted in sealed (pre-lubricated) bearings? No messy diff lube or casings to cobble

up.

And belts would be worth looking at as well, harder to find sprockets for but quite efficient and infinitely cleaner than a chain.

Cheers, Ted

[Edited on 16/7/04 by andkilde]

That's a good question Rorty" why go for a diff on such a light car".

If i was'nt such a chickenshit i would use a solid axle with minimum rubber suspension.It surely would simplify things enormously.

I also read so much pro's and con's on a two stroker for use in light cars that the confusion is complete.The same goes for suspension-live

axle without a diff seem to work perfectly for certain formula style light cars.

Perhaps i should look at it as a" gloryfied go-kart" instead of a car.

I would love to go the Rorty way but....

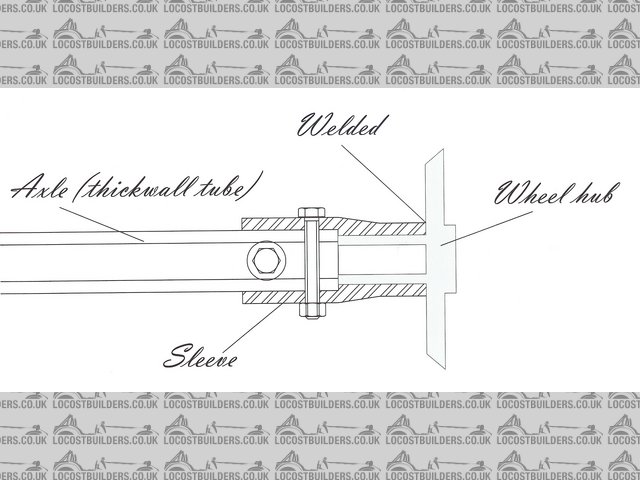

Suppose i would go for a solid axle without a diff have any of you guys got any idea on how to mount the wheelhub onto an axle in such a way that i can remove those hubs easely,

This is just an idea of how the wheel hub can be made removable.The sleeve is welded to the wheel hub and the sleeve/hub combination is bolted onto

the axle(thickwall tube)with two 1/2" high strenght bolts.I know it's certainly not the best engineering solution but could this

work?

Rescued attachment wheel hub.jpg

Oops,done it again HUUUUUUGE picture,sorry!

In the few autograss specials (like the one in my archive, which won again this weekend!!!) which use diffs with bike engines and chain drives (which mine doesn't!), they use escort LSD's from the ford "English" axle, bolt a sprocket to the crownwheel, mount the diff from it's original bearing locations on a pair of "plummer block" bearings, weld caps over two of the 4 round holes in the diff casing and weld a boss with a grease nipple in it into the third hole and a drill and tap another boss in the 4th hole for an m6 screw. The grease lubes the slipper plates and the pinion gears, you take out the m6 screw, pump in grease until it comes out of the screw hole and hey presto, maintenance free diff!. There are no other apertures in the diff apart from the 4 holes, and the plummer block bearings are sealed and have grease nipples so no oil supply needed there.

Thanks for the reply NSDev but i dont see the picture for me.

What is a plummer bearing block?

The sprocket replacing the crown wheel must be mighty small to fit inside the diff housing as i understand the housing is used? Aldo i only have the

Merc diff to compare with there is ample room to mount something bigger than the original crown wheel.

For the moment i have set the diff approach aside and strongly think about going the solid axle route with trailing arms.

3100 members and not one of them find it a bad idea to bold the wheelhub to a axle?

That's VERY hard to believe on this forum

Or nobody is interested,could also be the case

Or even worse,nobody is interested in my car

OK Cita it's a shite system.... what you should do is drawn badly below - it's all DIY able if you have a lathe. The key is a 1/4"

round pin, you drill along the taper from the nut end so the pin fits nice and the nut keeps it in. Hope it makes sense

Cheers

Bob C

Rescued attachment flange.GIF

Thanks Bob,that's at least an honest answer.

I used the sleeve system 'cause than the original wheelhub could be used and a simple lathe job(which i have to hand out) would do it,obviously

not.

I am interested in the lsd with the holes blocked up & fitted on the plumbers block bearings, exactly what type of diff is it, is it the Atlas

style?, can any other type be used? if so suggestions would really help.

What grease would you suggest?

quote:

Originally posted by ja99a

I am interested in the lsd with the holes blocked up & fitted on the plumbers block bearings, exactly what type of diff is it, is it the Atlas style?, can any other type be used? if so suggestions would really help.

What grease would you suggest?

quote:

Originally posted by Cita

Thanks for the reply NSDev but i dont see the picture for me.

What is a plummer bearing block?

The sprocket replacing the crown wheel must be mighty small to fit inside the diff housing as i understand the housing is used? Aldo i only have the Merc diff to compare with there is ample room to mount something bigger than the original crown wheel.

For the moment i have set the diff approach aside and strongly think about going the solid axle route with trailing arms.