Front wishbone mounting advice

MikeRJ - 30/5/04 at 01:21 PM

With all the nice weather, I have been motivated to drag the locost chassis out and get cracking. Tacked the front lower wishbone brackets and shock

mounting brackets on yesterday, all looking good.

Started on the upper wishbone moutning today, and have run in a couple of snags. The chassis is a +4" wide and +1" tall version, which

obviously causes the angle of the FU tubes to be different to book.

First problem is that if I set the two wishbones parallel when they are horizontal as the book states, the transit rod end binds up on droop with

about another 3/8" of damper movement to go. The obvious cure is to move the top wishbone brackets slightly down the tubes. However, this is

obviously going to change the geometry, causing more negative camber at full bump. Is this likely to cause problems?

Problem 2 is that the two top wishbone brackets are not perfectly in-line with the chassis, i.e. a long 12mm bar put through both brackets is not

exactly parallel to the chassis, but points outward slightly (not huge amount, but enough to be visible without measuring it). Should I leave it as

is, or pack out the front bracket slightly?

James - 30/5/04 at 02:23 PM

It's worth getting it right otherwise at the back of your mind you'll never be happy with the handling of a car you've spent so much

time on!

Have you made a jig? There's a couple fo pictures in my archive of mine- it was well worth it and meant the brackets took about 5 minutes to put

on!

http://www.locostbuilders.co.uk/photos.php?action=showphoto&photo=bracketjig_fr_small.jpg

http://www.locostbuilders.co.uk/photos.php?action=showphoto&photo=bracketjig_rr_small1.jpg

You could use MDF or something instead of the 19mm bars if you don't have any spare.

The key with putting the brackets on is to find a datum point about which to set them all. The only static ones are the lower rear brackets. Once

these are clamped in place you can set all the others around them.

If you haven't made the LA/LB assembly correctly then LA/LB won't be paralel to the chassis- I guess you can pack these to compensate but it

would be better to get it right in the first place! Mine took 2 or 3 attempts!

Finally, I would keep FU1/2 loose until the brackets are hanging in place- then set FU1/2 to match the brackets as opposed to vice-versa.

Hope that makes sense!

James

MikeRJ - 30/5/04 at 03:53 PM

The jig method is a great idea, and I'm sure would work very well, but the problem is that I cannot physicaly locate the brackets where they

should be due to the angle limits of the rod ends.

I've just been "playing" with with the suspension, and I have come to the conclusion that there is absolutely no way I can safely get

the wishbones parallel unless I a) get some shorter dampers, or b) find a transit rod end that allows more movement.

The shocks I have are Spax units from a Westfield, and splashing out on new units is not really feasable at the moment with a potential work

redundancy hanging over my head. It's possible that aftermarket rod ends may vary in the maximum useable angle, but not by much I'd have

thought.

What I really need to know I guess is how much movement should be left in the rod end when the suspension is at full droop, to allow for bushes etc.

flexing?

JoelP - 30/5/04 at 03:58 PM

quote:

Originally posted by MikeRJ

First problem is that if I set the two wishbones parallel when they are horizontal as the book states, the transit rod end binds up on droop with

about another 3/8" of damper movement to go. The obvious cure is to move the top wishbone brackets slightly down the tubes. However, this is

obviously going to change the geometry, causing more negative camber at full bump. Is this likely to cause problems?

this will also possibly cause positive camber in droop, before it drops further and goes back negatige.

top wishbones from MK (maybe others too) point upwards to help sort this problem, is it too late to change them?

i had similar problems with my bottom joint reaching full travel early, i just adjusted my ride height to compensate.

edit: when setting mine up, i connected the bones to the hubs without a spring, and measured how far it could travel. About 4 inches. I then put the

shocker bottom bracket on so that the wishbone couldnt fall all the way to the limit, and then made the spring a little pre compressed to reduce the

travel in bump.

Obviously this is nothing to do with how you position the brackets, its just how i solved the travel issues...

easiest thing seems to be changing the upper wishbone in my view, had to remake my lower ones to make it work properly.

[Edited on 30/5/04 by JoelP]

MikeRJ - 30/5/04 at 04:34 PM

quote:

Originally posted by JoelP

easiest thing seems to be changing the upper wishbone in my view, had to remake my lower ones to make it work properly.

[Edited on 30/5/04 by JoelP]

Thanks for the suggestion, that's not a bad plan (seems obvious now you've mentioned it!). Certainly a whole lot cheaper than a set of

shocks...

Thinking about it I guess I could move the shock bracket on the lower arm more toward the ball joint, which would have the added advantage of reducing

the much discussed bending moment that it introduces. Will also lower spring rate though...

[Edited on 30/5/04 by MikeRJ]

MikeRJ - 30/5/04 at 08:18 PM

Update: I had a spare transit drag link end, so investigated the possibility of increasing it's travel slightly. Ten minutes with the dremel

and it doesn't quite bind up at full droop, but zero margin for bush deflection etc. The amount of metal I had to remove was miniscule, so could

be modified to move further, but I'm not overly happy about doing this.

Something interesting though, I was looking at James jig, and checked the book for the correct distance between the upper and lower wishbone pivots.

The book says 8", but with my wishbones (Luego) I need to mount them around 10.5" apart to get the wishbones parallel. Does the Maxi

balljoint raise the hub up significantly compared to the Cortina ones? If not where is this extra 2.5" comming from?

I've put a few pictures in my photo archive if anyones interested.

paulf - 30/5/04 at 09:19 PM

Are you sure that you want the wishbones parellel when horizontal?

I think on most cars the top wishbone points upwards at the outer end when the bottom wishbone is horizontal, I know mine does but not sure by how

much without going to the garage.

Paul.

[quote.

First problem is that if I set the two wishbones parallel when they are horizontal as the book states, the transit rod end binds up on droop with

about another 3/8" of damper movement to go. The obvious cure is to move the top wishbone brackets slightly down the tubes. However, this is

obviously going to change the geometry, causing more negative camber at full bump. Is this likely to cause problems?

Peteff - 30/5/04 at 10:14 PM

The pivot points should be level, not the actual wishbones. The increased negative camber on full bump is a good thing as it will keep the outside

tyre more in contact with the road as it is being loaded, that's the idea. Don't overthink it or you'll never be happy with it. Put

some bump stops in the damper if you think it will ever get to full travel and bind the top joint.

MikeRJ - 30/5/04 at 10:38 PM

quote:

Originally posted by paulf

Are you sure that you want the wishbones parellel when horizontal?

I think on most cars the top wishbone points upwards at the outer end when the bottom wishbone is horizontal, I know mine does but not sure by how

much without going to the garage.

Paul.

[quote.

Not sure at all, jut going by what the book says, it's pretty vague to be honest. If I follow the book measurements to the letter, then the top

wishbone will very definately be pointing upwards from the car, and there won't be any problems with binding.

I also though a little more -ve camber may not be a bad thing, but as James says, I'll be a little unhappy if it handles like a barge after all

the effort that will be put into it.

Steve Hnz - 31/5/04 at 04:48 AM

Mike not sure which edtion of "the book" you`re using but if you look at photos of finished cars in the 2nd ed then its plain to see that

all of them have top wishbones that are inclined up from the chassis to the top ball joint. Stick to the book measurements re spacing & follow

James advice on how to proceed. As you are using Cortina uprights then using a flat top wishbone & the correct setup will give you all the travel

you need. Once you get this Correct you can then set up your top shock mount to match the shocks you`re using. Again if you look closely at photos in

the 2nd ed or photos from various archives on this site you will see that different shocks require different positioning for their mounts taking into

account their length & range of travel. "The book" is just a guide in this area, & if you follow James advice the order of

completion should probably be, bottom mounts, top mounts , shock mounts. HTH , Cheers Steve.

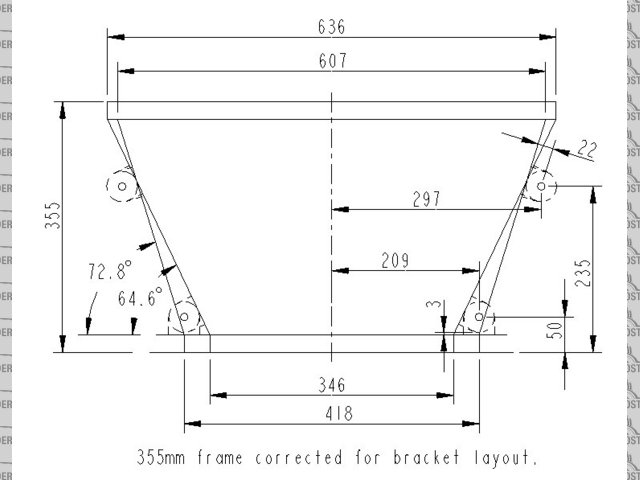

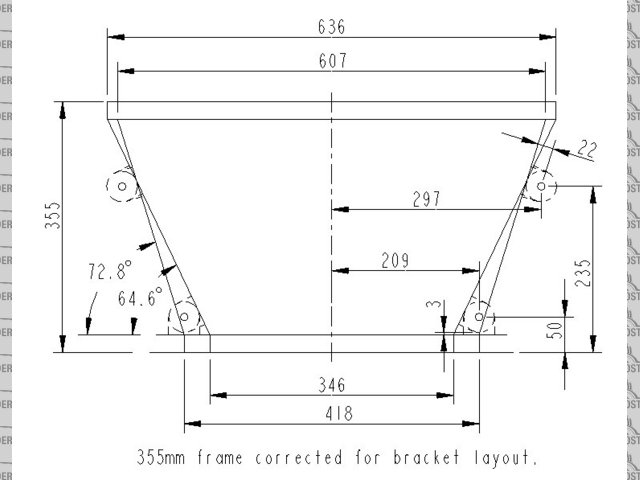

leto - 31/5/04 at 06:49 AM

This might help some.

Drawing of 355mm front and brackets

Cheers!

Mix - 31/5/04 at 07:17 AM

As I understand it the front wishbones should diverge.

My set up is not exactly as per 'book' but it's pretty close. With the lower wishbone pivots / ball joint centre line horizontal the

upper ball joint centre line is about 30mm above the upper wishbone pivots.

HTH Mick

davef - 31/5/04 at 11:41 AM

Hi mikeRJ

The top wishbone should angle down toward the bottom of the car, the reason is for the correct positioning of the roll centre of the

car, if you look at the car front on at wheel ctr height and imagine a line coming from the top and bottom ball joints passing along the center of the

wishbones, to the other side of the car then those imaginary lines should converge round about the bottom ball joint at the other side. this is about

as good as you will get it on a locost. cheers davf.

MikeRJ - 1/6/04 at 07:53 AM

Thanks for all your help, it makes things so much easier when you can ask people that have "been there before".

I guess I have just misinterpreted the book, and as suggested I am just making things complicated for myself. I've got enough bits of scrap

together to make a jig so hopefully I'll have the brackets in place this evening.

Peteff - 1/6/04 at 09:40 AM

When it's on its wheels it will never reach the angle you are looking at unless you are thinking of jumping buses with it. The only time it will

reach that angle is when you jack it up and I don't think the stress of that will cause any damage. There will only be the weight of your

components on it for a short time as you change wheels or fix brakes. The problem would be if it binds in the other direction which it shouldn't

if you are o.k. with your measurements.

stephen_gusterson - 1/6/04 at 09:53 AM

I had no end of trouble with the top joint.

In my case it was due to using sierra hubs... is that what you are using?

I found that even when at full droop, moing the steering caused the hub and suspension to rise as the rotation of the joint caused its stop position

to change.

Its all down to the angle of the top of the sierra strut holder. The joint is already set at several degrees from level, even when the suspension is,

if you get my meaning.

Take a look at the wishbones from an MK indy. The transit joint threaded tube is ANGLED to suit the top of the hub, such that at level suspension

position, the joint is in mid travel.

Here speaks one from bitter experience. I had to make my upper wishbones and mounting system twice....

atb

steve

[Edited on 1/6/04 by stephen_gusterson]