Lotuses(18/24/25)-like rear bulkhead

jcduroc - 13/3/04 at 12:01 AM

Can clear my doubt on how is that sort of bulkhead isbuilt?

Is there round (or square) tubes inside the two holed sheet panels? Which gauge (tube and sheet)? Is everything welded all around?

Would it be asking too much if someone could make a simple sketch of how to build such a bulkhead?

Thanks a lot

Cheers

Joćo

Alan B - 13/3/04 at 12:58 PM

Hey guys...can someone just look in "high speed-low cost"......I'm certain the answer is in there.....I'd look myself but my copy

is out on loan right now...

MikeR - 13/3/04 at 11:31 PM

I haven't got mine handy but i asked a similar question a while ago. The book (without plans) doesn't cover it. In the terrapin i'm

sure tha answer came back being roung tube bent into the circle shape. Thickness etc ... no idea, sorry.

robinbastd - 13/3/04 at 11:46 PM

Just had a quick whizz through HSLC and I could see no mention other than the sq section sizes which are on the small side for a road car and thin

sheet steel. The sheet is welded on both sides of the sq section tube and the holes are swaged. Mr Terrapin racing will be able to tell you much

more.

Ian

jcduroc - 16/3/04 at 02:28 PM

quote:

Originally posted by robinbastd

Mr Terrapin racing will be able to tell you much more.

Ian

It seems Mr.Terrapin Racing is more prone to keep its stuff than to sharer it...as it's supposed to be in this forum!

Joćo

Terrapin_racing - 16/3/04 at 02:38 PM

Joao, happy to share any techy details.

Sorry your upset, but I assure you I send a detailed note to your hotmail account some time back... anyway, here we go again.

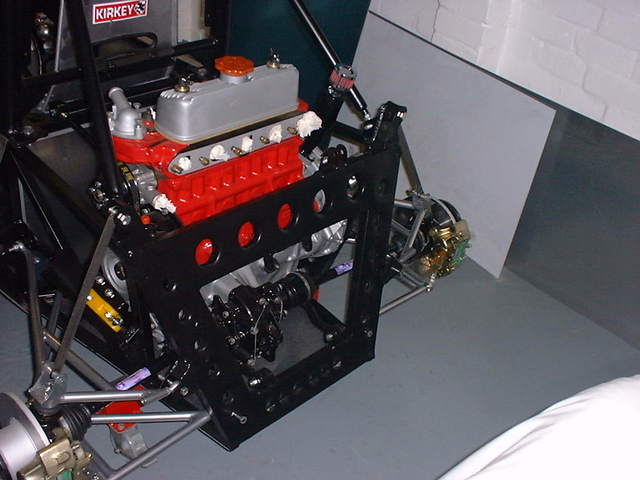

The rear bulkhead is 16g x 0.75 inch square tubing skinned with 16g sheet steel. The holes are for lightening the structure. I am just about to send

the tool I made for radiusing the holes to a builder in Scotland.

Give me a few minutes and I'll knock up a sketch of the bulkhead from memory (plans at home)

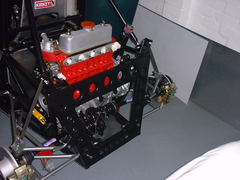

Rescued attachment DSCF0022.JPG

Terrapin_racing - 16/3/04 at 02:42 PM

swaging tool - being lent to a builder (that's what I call helpful!)

Tool is made from Lignum Vitae (a very very hard/heavy wood once used for ships bearings as it contains a self lubricating oil - actually sinks in

water!)

Rescued attachment DSCF0030.JPG

ceebmoj - 16/3/04 at 02:53 PM

only just seen the thred other wise I would have put up some pictures

Terrapin_racing - 16/3/04 at 02:55 PM

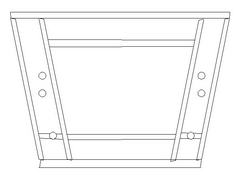

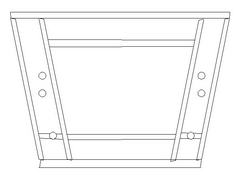

see crude hand sketched (quick and dirty on visio!) drawing of tube arrangements

Rescued attachment rearbh.jpg

Terrapin_racing - 16/3/04 at 02:55 PM

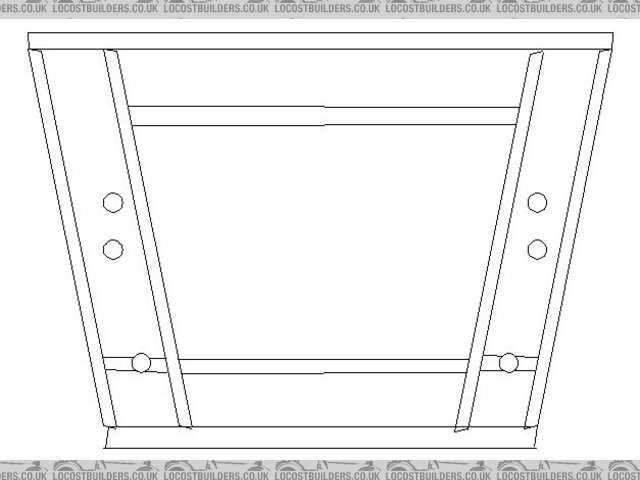

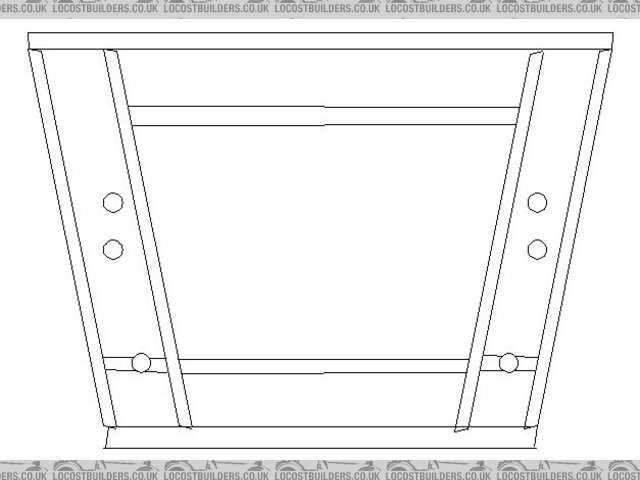

see bottom left on plans also

Rescued attachment plans1.JPG

Terrapin_racing - 16/3/04 at 02:59 PM

Sheet steel is spot welded at 1.5 inch intervals to the tubes - or you can braze at regular intervals. All holes were cut and formed prior to

attaching the front / rear skins.

Then the 3/8inch bushes were brazed in place (for suspension rosejoint pick ups and anti-roll bar mounts.

Anything else I can provide?

Terrapin_racing - 16/3/04 at 03:16 PM

Front bulkhead is 1/2" round tube - an inner oval and an outer oval formed around an mdf pattern prior to welding on the 16g skins - holes formed

in same fashion as rear.

Joao, if you mail me your address I'll send you a present - don't jump on the band wagon guys !!

[Edited on 16/3/04 by Terrapin_racing]

jcduroc - 16/3/04 at 03:20 PM

quote:

Originally posted by Terrapin_racing

Anything else I can provide?

Thank you "Terrapin Racing".

I'm sorry for misjudging you but in fact I didn't receive your post at Hotmail.

Your info is (for now) sufficient and I'm (now) sure that, if needed, you'll be avaible to provide more info.

Thank again

Cheers

Joćo

jcduroc@yahoo.co.uk

joaomatoso@hotmail.com

jcmatoso@netvisao.pt