Hi, i have been told that when your setting yourself up for a kit car build you need to stock pile washers and drill bits. I am building an Aries

locost, what sort of sizes will i need ..

That's a tricky one. I would firstly get some big ones, then, get some small ones and some sizes between the two.

That should cover it.

Common bolt sizes are 5,6, 8, 10 & 12 mm.

Rivet sizes are often 3.2 & 4.8 but can be lots of different sizes and go up in in 0.5mm increments.

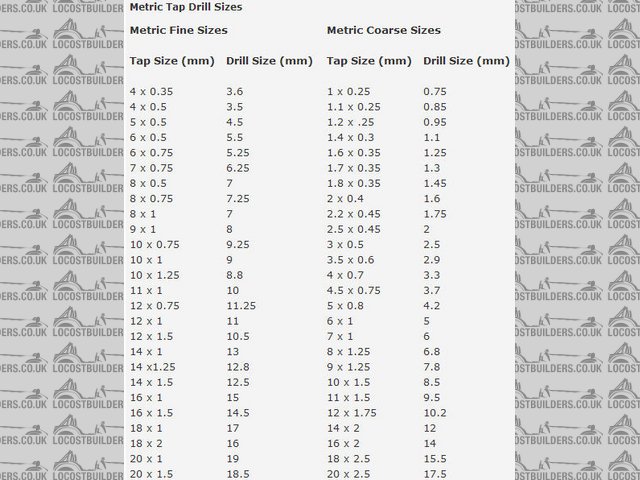

Tapping drill sizes are:

Description

[Edited on 14/10/08 by Litemoth]

I seemed to get through several 4, 5 and 6mm drill bits

Get a Decent set, 2mm up to 13mm in .5mm increments.... (I think my set came from Axminster in a nice metal box)

Then get some spare 3, 3.5, 5, 5.5 and 6mm drills....

(Obviously if you are doing some tapping, get some appropriately sized drills)

Learn how to sharpen drills properly using a grinding wheel....its not hard, but deffinately a good skill to have...

If you are drilling stainless steel get osme Cobalt stub drills....pricey, but they wont burn out as quickly as HSS ones!

With regards to washers.... Deffinately....GO through the screwfix catalogue and get a couple of boxes of 6, 8 and 10mm washers, both standard and

large penny size....their BZP ones are acceptable....

Get an assortment of bolts and nuts as well...Their bolts are not amazing, but for most things they are suitable

[Edited on 14/10/08 by tegwin]

I bought a pack of 10 * 5mm drill bits from Screwfix as everyone said I'd break loads of them.

I managed to drill the ally floor pan and the chassis using the same same bit - I didn't need the others.

You just need to maintain a steady pressure and the drill bits will be fine. It's when you just lazily drill that they break or wear prematurely.

Two golden rules;

1/ When using drills keep them lubricated 2/ Don't buy anthing with Clarkes written on it.

quote:

Originally posted by LBMEFM

Two golden rules;

1/ When using drills keep them lubricated 2/ Don't buy anthing with Clarkes written on it.

Ibought a set of 1 - 13 in 0.5mm increments and also a set of 1 - 6 in 0.1mm increments. Tracey tools do good deals on these. You will snap the rivet

sizes due to amount of use they recieve so good idea to buy some replacements at same time.

I also bought a sets of washers, self tappers, bolts, nuts etc as i needed them from local engineering suplies place. They come in very handy, but be

warned it can be a fair bill if you get them all up front, hence why i got them as needed.

Cable ties, rivnuts etc are all usefull as well. Its almost impossible to come up with a list before you start the build. It all depends if you are

buying a complete kit Caterham stylee or planning to fabricate some parts yourself to keep costs down.

Try Chris mason for some of the common fasteners.

And as Jacko says, get yourself a few pairs of decent safety glasses. When i have projects on the go i like a pair in each corner of the garage, that

way you have ne excuse to reach up and pop them on. Its really surprising how easy it is to take short cuts and not bother when you have to down tools

and search for 5 minutes for a pair.

I got myself an old aircraft hostess trolley to put all fasteners, tapes, ties etc in. Dont take up much room and keeps everything east to hand

(similar storage cupbards of course do same job).