Chassis Modifications

Dan. - 30/12/13 at 10:15 PM

Hi Guys,

I have decided I'm going to get my chassis re-powder coated since I am now adding a roll cage, so thought I would take the opportunity to make

some chassis modifications whilst I am at it...

The chassis is an Original MK Indy.

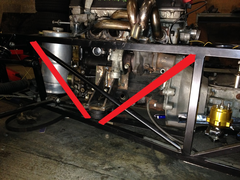

My plans are as follows, add triangulation to the front.

Description

Add triangulation back to bulkhead unfortunately there is only room to do this on one side as turbos(yes two!)/manifold will be in the way, unless its

worth while triangulating part way as per the blue in lower pic?

Description

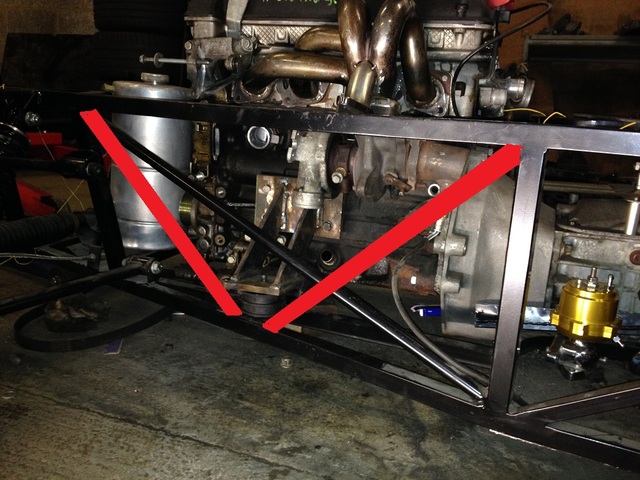

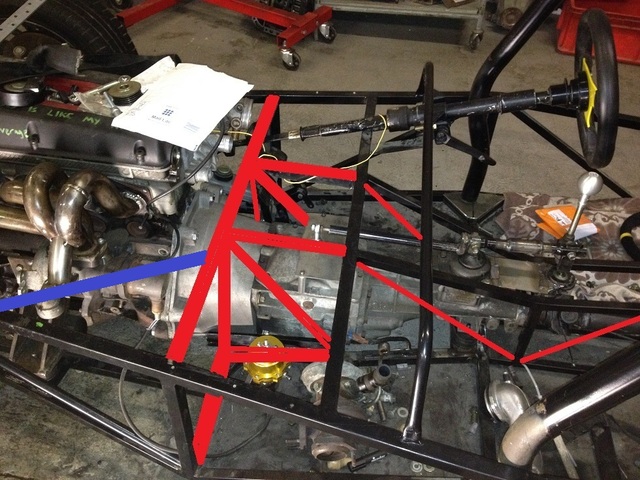

Next Up is around the engine mounts, do you think I would be best off removing the existing triangulation front to back and replacing as per below?

this setup will have a lot of torque (will be in the region of 450bhp with torque to match) I'm aware there is noting substantial where the

engine mounts are currently located. And yes I am aware my current engine mounts are a little over engineered ha.

Description

Next up when faffing around with turbo plans I removed a big chunk of my chassis... obviously this now needs replacing..

This is how it currently stands

Description

What I'm proposing

Description

Triangulate the tunnel

Description

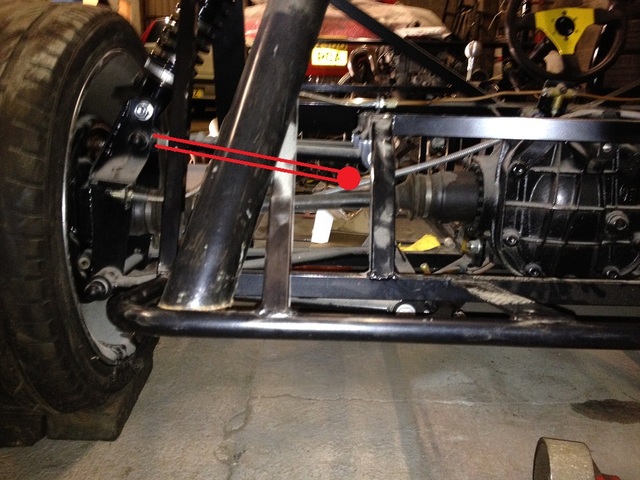

Move rear upper suspension pickup down wards and outwards, and remake wishbones 1.5" shorter to match, this should improve the camber issue

that's present on the original MK Indy, and also raise the centre of roll helping the car to corner flatter.

Description

I will also triangulate this area but not given it much thought yet, and don't have a decent pic to hand.

Anyway if anyone would like to point out any flaws to my plan or other potential improvements

mark chandler - 30/12/13 at 10:28 PM

You only need one diagonal at the front.

Rather than add diagonals to the tunnel and bulkhead weld in 1/6" steel.

Here's mine

Chassis painted inverted

Chassis inverted side painted

Regards Mark

Dan. - 30/12/13 at 11:07 PM

Ok so from this....

Description

To something like this (Also moved the inner rails inwards to triangulate further)

Description

Is there any reason MK have bent the lower rail so its made out of one piece rather than welding straight section?

mark chandler - 31/12/13 at 12:00 AM

You will have to ask MK

Have a read of the thesis word docs

Here

Then for the stuff I followed kitcaranalysis_V2.doc

[Edited on 31/12/13 by mark chandler]

Dan. - 31/12/13 at 12:18 AM

Thanks not seen them before will have a look

Dan. - 31/12/13 at 03:08 AM

Given the restrictions I have around my engine I have come up with the following

Description

Or given I do not need a deep passenger foot well, and could do with the extra space in the engine bay...

Description

If anyone would like to suggest changes attached below is a blank

Description

[Edited on 31/12/13 by Dan.]

Dan. - 31/12/13 at 03:16 PM

No other opinions before I buy some steel and get mr angry grinder out?

fregis - 1/1/14 at 12:07 AM

not need so many diagonals, one of the diagonals in square strengthens enough, ant try "connect" diagnals.

to engine mounts diagonal are good, but enough one

Under engine i put screw reinforcement

Also put in corner (at diagonal) triangle plate stiffeners, at reduced tension of the welding seam

i have found few documents to frame stiffness optimization. email or need somewhere upload

light weights and stiff front:

how think about that?

blue one nood need- becaus engine at the point pull, other side press

[Edited on 1/1/14 by fregis]

Dan. - 1/1/14 at 01:16 AM

Cannot do the right Y brace due to the locations of the turbo's, manifolds and wastegate's unfortunately, or the cross brace as that's

where the oil tank fits and belts etc.

though you are right I probably have gone a little over the top on triangulation.

[Edited on 1/1/14 by Dan.]

mark chandler - 1/1/14 at 01:31 AM

Roll hoop and petty strut will stiffen the centre of the car

sebastiaan - 1/1/14 at 10:43 AM

Hi,

Have a look here:http://locostbuilders.co.uk/viewthread.php?tid=148892 for inspiration. Made a definite improvement to steering feel.

Dan. - 1/1/14 at 08:54 PM

Thanks for the input, dismantling the rest of the car will take place tomorrow and I'll get the cutting done, hopefully my local suppliers have

what I need in stock. Also ordered a set of custom rear wishbones to match my new mounting points, I'll post pictures of progress and results of

the suspension geometry of the new bones and mounting points :-)

ashg - 2/1/14 at 02:03 AM

hey dan. good to see another saab user.

i have this brace on my car

you will have to do this to clear the saab water pump outlet anyway

or you can do this

your rear upright carriers will need beefing up, they will bend trust me!! box up the back of them and then make a hole for the driveshaft to go

through as the 3mm plate on the sides can bend.

sorry to say it if you have already spent out but i dont think your prop is up to it, i had to upgrade to a 4inch tube prop with lorry joints.

other than that great start.

couple of questions what box are you using? is it a bmw item? i went for the omega box its managed 3 years of my abuse so far!

and what are you doing with regards to dry sumping it? just running scavenge and keeping the standard pump or going the whole hog with a multi stage.

oil control can be a real issue with these engines in longitudinal format as i have found out on two occasions.

this is the wet sump layout im running now that seems to be ok, but i am considering drysump options for the future, your thoughts would be

interesting, if you dont have a solution yet then maybe we could knock heads together and develop a kit.

Dan. - 2/1/14 at 02:20 AM

Great post many thanks for replying! Water pump is not an issue as I have already modified mine :-) but will be altering the triangulation anyway.

Didn't know about any issue with the rear carriers, I will box them in as suggested though!

Did you break your prop then? What power were you running?

Gearbox is from a T5 box from a TVR, basically the same box as a cosworth 2wd ratio wise but with upgraded internals apparently, so gives nice ratios

and will hopefully last as it should be a fair bit stronger than the omega item.

I have a single stage scavenge pump pumping to the external tank, then feeding back through the modified sump to the standard oil pump, the setup is a

total doddle thanks to the sump design, did the same on a friends car and it worked a treat.

Good to know there is another saab engined car about, I only knew of one other which also was built in my lockup, where abouts in kent are you from? I

come down that way fairly regularly as I have family in Deal.

[Edited on 2/1/14 by Dan.]

Digimon - 2/1/14 at 01:45 PM

Looking good Dan

Dan. - 22/2/14 at 11:39 PM

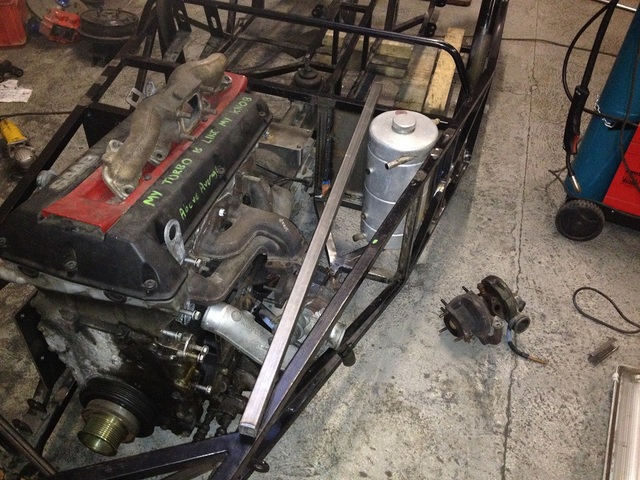

So I have done a little work on this recently....

First of all increased the size of the engine bay by eating into the passenger foot well...

Description

Description

Beefed up the front end with a little extra bracing and added 'r tube'

Description

Description

Description

Decided whilst I was at it I would re-design the rear suspension geometry..... (I can never leave things alone....)

Hello angry grinder... Out with the old...

Description

Description

Moved outwards and downwards...

Description

Decided I didn't like the contact area they had so made new...

Description

Change in position

Description

New rose jointed arms with custom shorter upper bones held roughky in place to see how it looked (thanks Danny@MK)

Description

thought about different bracing options...

Description

Cut all the bits for bracing and left it for my friend Adam to weld up for me.... clearly he got bored as I found this additional roll protection

welded to my car

Description

Welded up

Description

Mounts for cage welded in

Description

Engine in siute, yes the manifold does fit.... just, as does the dry sump pump

Description

Not sure what to do with the other side of the car yet, may put in a Y brace depending which manifold I use.

Description

Anyway that's it for now, the setup should hopefully strengthen things up nicely (when the engine bay is finished) and with the rear suspension

modifications the car should roll less due to the centre of roll being raised nearer the center of gravity and the negative camber in roll

significantly improved due to the shorter wishbones and repositioned upper mounts.

[Edited on 23/2/14 by Dan.]

scutter - 23/2/14 at 10:45 AM

Looking good fella, I've just added these 2 Y braces to the front of my engine bay and a removable one across the front. Could your Oil tank

either go into the passenger footwell or drop to the level of the underside of the chassis to allow a full Y brace?

Description

Regards Dan

Dan. - 23/2/14 at 12:25 PM

The oil tank is fine can position the Y brace round it, the issue is where the manifold is, I can get a y brace in there with the manifold that's

in the pic, but I'd prefer to use the tubular I have, when I get the alternator and water pump back I'll weigh things up.

Dan. - 25/2/14 at 11:16 PM

Collecting the waterpump and alternator tomorrow and have 3 days to make some progress, if anyone has suggestions for further improvements to the

chassis i'm all ears as id rather get any mods done before its powder coated... actually surprised no one has asked about the rear suspension

given The original MK Indy suspension geometry is a very talked about subject on here....

Digimon - 26/2/14 at 10:00 AM

Looking like you are making good progress mate

Dan. - 26/2/14 at 11:14 PM

Some more progress today, removed my external wastegate on my tubular manifold so I could fit in a Y brace, will have to reposition the wastegate when

I get some stainless tube.

Description

Description

Description

Description

Description