has anybody made there own paddleshift system,it doesnt look that hard to do,any pictures or advice on how to go about,im after makeing one my self because they seen a bit pricey for what they are.

I've never got any good photos to show anyone, but yes it is very simple... Here's a couple of (bad) pics of my polished/drilled Ali and

Carbon Fibre one...

paddleshift

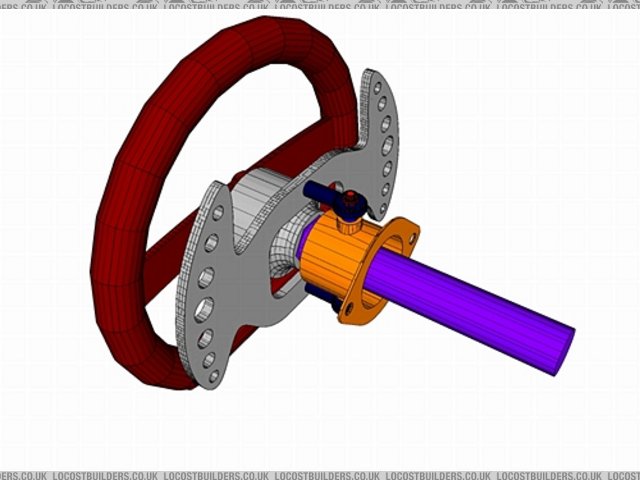

Here is mine.

I have not got a decent picture of it on the car yet.

Got andyw7de to waterjet the paddles.

SPA "D" shaped wheel on a quick release boss.

Here's our effort in 4mm Titanium. All CNC machined.

There are loads of threads on this subject. Do a search. People have used ali, mild steel,carbon, you name it. Water jet cut, laser cut, hacksaw cut

and filed,etc.

Cable or rod operation?

Use whatever method and material you can afford and that you can find locally.

Tell us where you are, someone may be able to recommend local help.

Geoff.

I made my own. I went with thinner ally than most use and reinforcing strips behind. Mainly because it was easier to work...and it's what I had.

I found be most important thing was reducing flex both in the paddle itself and the linkage.

http://i189.photobucket.com/albums/z282/adrianthorp/Picture036.jpg

http://i189.photobucket.com/albums/z282/adrianthorp/Picture034.jpg

http://i189.photobucket.com/albums/z282/adrianthorp/fury086.jpg

adrian

What may make a difference to the posts above is if you have and want to keep the switch gear on.

The way I did mine was to use the shroud mounting points to mount the plate to allow the paddles to move.

Description

I do have more pictures of the whole setup if you would like them U2U me and i will sort them out.

Its not hard to do as with any thing else its just a matter of taking your time. I did alot of drawing on paper cutting out and seeing how it looked

behind the ssteering wheel and how easy it would be to use.

it is actually fantastic I still have some minor mods to do to the system to move the paddles further away from the wheel but apart from that its

fine, I also run it via a cable system and have kept the stick shift working which uses a rod system.

Here is mine, propper locost style at about £8 all in i think.

May not look as flash as a carrbon / titanium/unobtainium version bit it does exactly the same job!

Its made out of push bike handle bar tube with a pair of those forward facing pushbike handle bar extensions you see on mountain bikes.

All sprayed up black it loos fine to me.

[img][/img]

See this thread

http://www.locostbuilders.co.uk/viewthread.php?tid=120866

Don't forget, should you choose cable operation, to pay particular attention to the cable mounting brackets. They need to be as rigid as possible

at both ends.

We have used a fabricated ally bracket at the paddle end, bolted to the chassis through welded in tubes. You could probably lift the car with it!!

The lower end is fabricated titanium. We just happened to have some offcuts lying around. And we get all our titanium for free (from the scrap bin) so

it's genuinely Locost.

I've seen some woefully flimsy contrivances that will ruin your efforts to achieve a crisp and positive gearchange.

Although we have used a cable setup I feel that a correctly engineered rod type setup might give the best change.

I got talked into using a cable.

Not wishing to open up the "cable versus rod" debate though. It's been done before.

The search button is your friend. You'll find lots of pics for inspiration.

Geoff.

thanks for all the info